Wellhead

Wellheads can involve dry or subsea completion. Dry completion means that the well is onshore or on the topside structure on an offshore installation. Subsea wellheads are located underwater on a special sea bed template. The wellhead has equipment mounted at the opening of the well to regulate and monitor the extraction of hydrocarbons from the underground formation. This also prevents oil or natural gas leaking out of the well, and prevents blow-outs due to high pressure formations. Formations that are under high pressure typically require wellheads that can withstand a great deal of upward pressure from the escaping gases and liquids. These must be able to withstand pressures of up to 140 MPa (1,400 Bar). The wellhead consists of three components: the casing head, the tubing head, and the “Christmas tree.”

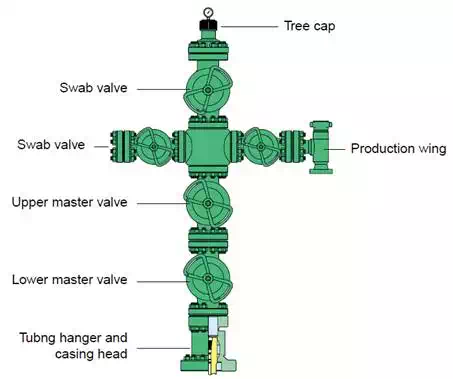

A typical Christmas tree, composed of a master gate valve, a pressure gauge, a wing valve, a swab valve and a choke is shown above. The Christmas tree may also have a number of check valves. The functions of these devices are explained below.

At the bottom we find the casing head and casing hangers. The casing is screwed, bolted or welded to the hanger. Several valves and plugs are normally fitted to give access to the casing. This permits the casing 33 to be opened, closed, bled down, and in some cases, allow the flowing well to be produced through the casing as well as the tubing. The valve can be used to determine leaks in casing, tubing or the packer, and is also used for lift gas injection into the casing.

The tubing hanger (also called a donut) is used to position the tubing correctly in the well. Sealing also allows Christmas tree removal with pressure in the casing.

Master gate valve.

The master gate valve is a high quality valve. It provides full opening, which means that it opens to the same inside diameter as the tubing so that specialized tools may be run through it. It must be capable of holding the full pressure of the well safely for all anticipated purposes. This valve is usually left fully open and is not used to control flow.

Pressure gauge.

The minimum instrumentation is a pressure gauge placed above the master gate valve before the wing valve. In addition, other instruments such as a temperature gauge are normally fitted.

Wing valve.

The wing valve can be a gate or ball valve. When shutting in the well, the wing gate or valve is normally used so that the tubing pressure can be easily read.

Swab valve.

The swab valve is used to gain access to the well for wireline operations, intervention and other workover procedures (see below). On top of it is a tree adapter and cap that mates with a range of equipment.

Variable flow choke valve.

The variable flow choke valve is typically a large needle valve. Its calibrated opening is adjustable in 1/64 inch increments (called beans). High-quality steel is used in order to withstand the highspeed flow of abrasive materials that pass through the choke, usually over many years, with little damage except to the dart or seat. If a variable choke is not required, a less expensive positive choke is normally installed on smaller wells. This has a built-in restriction that limits flow when the wing valve is fully open.

Vertical tree.

Christmas trees can also be horizontal where the master, wing and choke are on a horizontal axis. This reduces the height and may allow easier intervention. Horizontal trees are especially used on subsea wells.