Magnetic Particle Inspection

What is Magnetic Particle Inspection?

Magnetic particle inspection (often abbreviated MT or MPI) is a nondestructive inspection method that provides detection of linear flaws located at or near the surface of ferromagnetic materials. It is viewed primarily as a surface examination method.

Magnetic Particle Inspection (MPI) is a very effective method for location of surface breaking and slight sub-surface defects such as cracking, pores, cold lap, lack of sidewall fusion in welds etc in magnetic materials.

There are many different techniques. The most versatile technique is using a 110v AC hand held electromagnetic yoke magnet, a white strippable paint as contrast background and a magnetic "ink" composed of iron powder particles in a liquid carrier base.

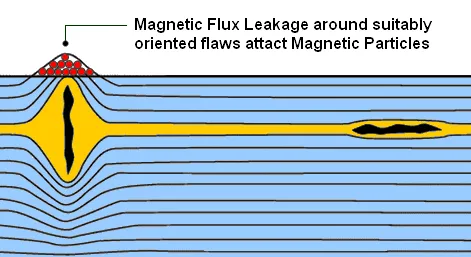

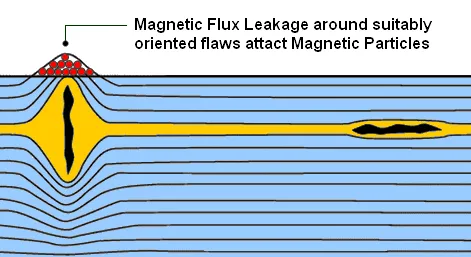

The area is magnetised with the yoke magnet. In the event of a surface or slightly sub surface defect being present, the lines of magnetic force will deform around the defect.

The magnetic ink is applied and the iron powder particles will bridge the gap caused by the defect and give a visible indication against the white contrast background.

Magnetic Particle Inspection (MPI) provides very good defect resolution and is used extensively on:

Welded fabrications in magnetic material, Castings, Locating fatigue cracks in items subject to cyclical stress

Schematic of flux lines flowing past both a perpendicular and parallel defect,

and flux leakage occurring around the perpendicular flaw.

MAGNETIC PARTICLE INSPECTION IS PERFORMED IN FOUR STEPS:

ADVANTAGES OF MAGNETIC PARTICLE INSPECTION