Solving NDT Demands with the Right Products

TecScan offers a wide array of NDT solutions and software designed to cover the aerospace, industrial and oil & gas industries. For nondestructive manual testing, our clients quite often know what they need, since companies in this field have an extensive background in NDT, as a supplier we do not usually need to walk them through which system and software combination is most important. In this case we may only have input as to what our best possible offer is to our clients demands. Whereas, clients looking for new NDT solutions in order to test structures with advanced technologies such as; new aircraft with integrated composite materials or complex aircraft engines components with new inspection challenges, thus instead of relying on conventional NDT inspection technologies, we must provide case specific and custom solutions. When such clients contact us in need of a solution; they aren’t always sure what they need in terms of both software and hardware. Our expertise allows us to assess the necessary NDT solution and also supply it.

In the case that a client is unsure what to purchase but knows what object must undergo NDT, we must ask ourselves the following questions: Which industry are we supplying? What is the volume of products being tested? What are the types and sizes of the defects we need to detect? What is the company’s budget?

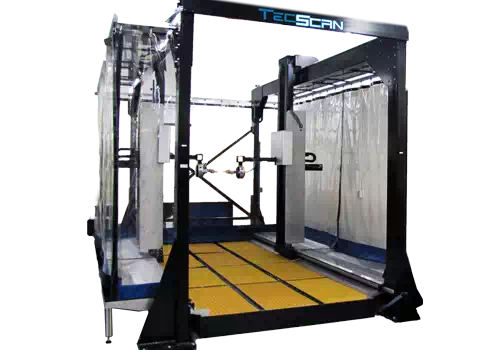

For Example: An automated gantry system would be recommended over an immersion system primarily based on the size of the tested objects. Gantry systems are versatile and well suited for automated testing of aerospace structures which are made of composite materials. Such gantries use ultrasonic probes with water squirter systems, articulated gimbals and turntables to reach difficult corners on the inspected parts. Therefore while still using water as a medium, the Gantry systems only apply water to the inspected points.

Side-Arms Gantry system

On the other hand 3D immersion systems are recommended for relatively smaller but still complex parts with curvatures. This series of systems are commonly recommended for manufacturers requiring very high detection reliability, resolution and repeatability. Our standard TSIS series tanks or the custom design solutions depend on whether the object is a simpler or more complex geometric shape, respectively.

Our signature software TecView™ comes in different forms also. For example, we would suggest our TecView™ 3D for applications which require full tridimensional and arbitrary motions of the system. Such a capability is among the most complex and demanding in terms of both electronics and software development efforts. TecView™ 3D allows users to import CAD files of the inspected parts, teach and learn the parts, perform full 3D inspections as well as generate accurate inspection C-scan images for analysis and interpretation.

We also would suggest our TecView™ EC software instead of our TecView™ UT software if the sole goal of the system is to test for damages on the surface of the material. Eddy Current testing is mainly used for subsurface crack detection in conductive material. In the case of ultrasonic testing, internal flaws are detected and C-scan images are created to map materials as a whole.

All software’s can be paired with any system and since the collective ensemble is all TecScan made, under a true manufacturer, they are easily compatible. If issues do occur on our clients end, it is a simple to contact TecScan support, all major components come from TecScan, and therefore TecScan would have all the necessary resources to apply any sort of repairs, assistance and even tutorials.