Ultrasonic C-Scan Imaging for Evaluating the Integrity of Brazed Parts

Ultrasonic Testing and C-Scan imaging represents a powerful NDT

technique for testing the integrity of metallic brazed parts. Metal-to-metal

brazing solutions are found in key sectors such as the aerospace, automotive

and nuclear industries, where high quality components are manufactured with

increased strength, fatigue tolerance, corrosion and oxidation resistance.

Brazing is a well-known method for bonding two metallic parts. As opposed to

welding where metals are melted to create a bond, brazing is done by melting a

filler metal into the metal-to-metal joint . Once liquefied, the filler metal

wets the surface and flows into the designed tight gap between the parts by

capillary action, creating a strong bond between the parts.

The integrity of the brazed joint depends on the proper wetting of the gap

created by the filler metal. In brazed joints, void defects can be formed in

the bonded area due to lack of brazing or incomplete wetting which can lead to

early component failure and poor performance.

Ultrasonic C-Scan for Braze Bond Testing

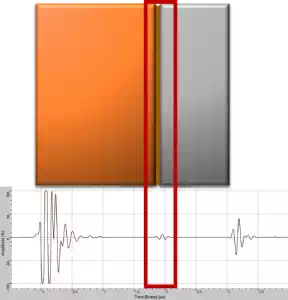

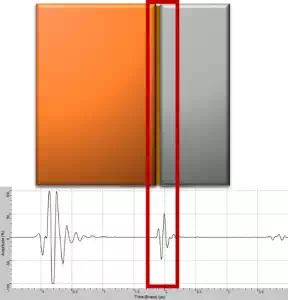

Voids in the bond area can be detected by monitoring the ultrasonic echoes reflected from the bond between the two materials. When performing ultrasonic pulse-echo testing on a brazed part, the amplitude of the echo provides the indications from the voids while the C-Scan shows the voids sizes and total area, thus revealing the overall bond quality.

Weak echo (low amplitude):

A good bonding in the brazed area results will provide Weak echo since the

ultrasounds can easily transmit from one material to another.

Typical Echo from good bonded brazed joint

Strong echo (high amplitude):

A lack of mechanical bonding in the brazed area results, will provide strong echoes

from the interface of the brazed area. The echoes represent reflections from

voids created due to lack of brazing.

A Typical Echo from bad bonded brazed joint

To perform complete inspection of a brazed joint for aerospace components or industrial parts: automated, immersion ultrasonic testing is used, providing C-Scan images and accurate bond quality evaluation.

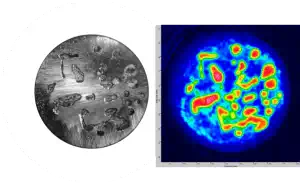

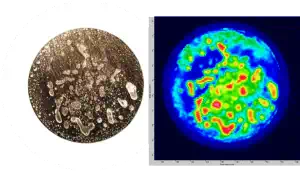

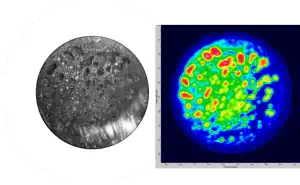

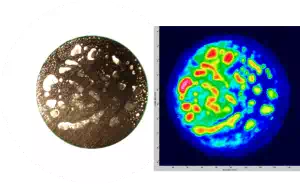

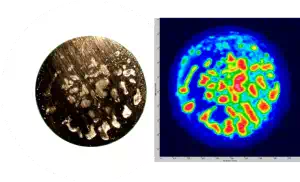

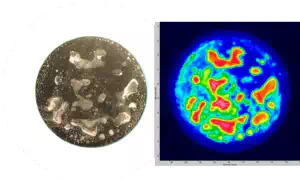

Brazed Silver-Copper Electrical Switching Contacts

A series of silver-copper samples presenting voids in the metal-to-metal brazing was inspected using immersion ultrasonic testing and compared to a metallurgical analysis, performed after precision ground (smoothing of the surface) to reveal the voids. As a reference, the diameter of the parts is approximately 15 mm.

Comparison of metallurgical analysis and corresponding C-Scan images of voids within a silver-copper brazed joint