PRINCIPLE OF DIRECT PRESSURE (DROP) TYPE AIR LEAK TEST

In this method, a leak is detected by charging test pressure to the work and measuring the change in the test pressure in the work after a given time.

Relationship of pressure change and leak inside the work

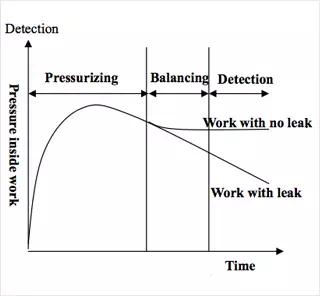

Pressure change inside the work during the air leak test is shown in the right figure. Pressure inside the work sharply increases during the pressurization process. This is because the temperature inside the work increases by pressurization and affects the pressure. The pressure change by temperature and other effects is stabilized (balancing process) and then the leak is measured (detection process). Constant value will be maintained and no pressure change in work will be detected when the work has no leak. However, the value will decrease at a constant rate due to decrease of pressure inside the work when the work has a leak. The direct pressure type air leak tester detects leak of work through this pressure change and judges the result.

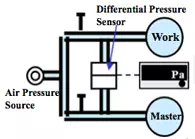

PRINCIPLE OF DIFFERENTIAL PRESSURE TYPE LEAK TEST

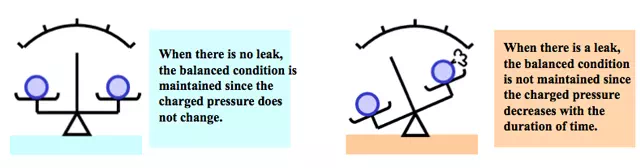

In the field of medicine, the use of a balancing scale is often used as a precise method for calculating arbitrarily small amounts of substance. The instrument is used to precisely measure a weight close to the balancing weight (a reference value) by increasing the weight value on the opposite side. The differential pressure type air leak tester uses the same principle as the balancing scale. The same air pressure is charged to both the work (tested work) and the master work (work with no leak) and the change in pressure balance within a fixed time is checked for the presence of a leak.

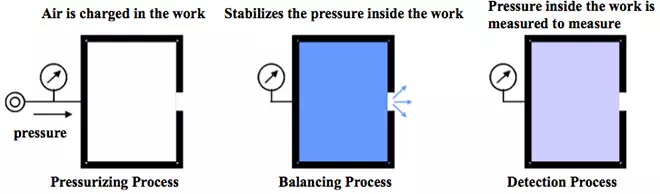

For the differential pressure type leak test, the leak test is performed through four processes; pressuring, balancing, detection and exhaust.

|

Pressurizing Process |

Balancing Process |

Detection Process |

|

|

|

|

|

Charge air in the tested work and master work. |

Close the valve and wait until pressure inside the tested work stabilizes.When there is a leak, air flows out and the pressure inside the work decreases |

Detect and measure the pressure difference between the tested work and master work through the differential pressure sensor. |

Relationship of pressure change and leak inside work

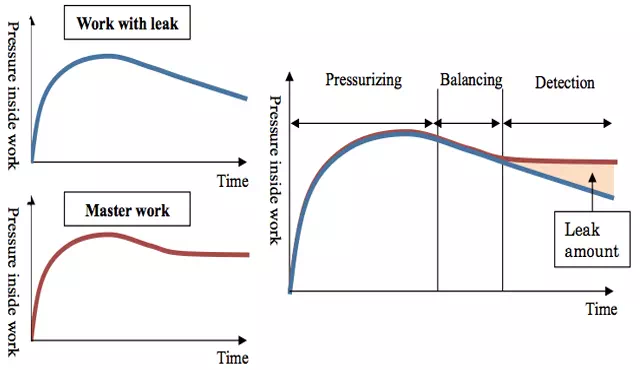

Pressure change inside the work during the air leak test is shown the below figure. Pressure inside the work and master work sharply increases during the pressurization process. This is because the temperature inside the work and master work increases by pressurization and affects the pressure. The pressure change by temperature and other effects is stabilized (balancing process) and then the leak is measured (detection process). After the balancing process, the constant value will be maintained with no pressure change in the master work since it has no leak. However, when the work has a leak, the value will decrease at a constant rate due to decrease of pressure inside the work. Also, when the work does not have any leak, the constant value will be maintained with no pressure change inside the work. A leak is detected by calculating the difference of pressure change between the master work and work.

FUKUDA provides various models of differential pressure type air leak testers. FUKUDA also has a lineup of products with additional functions according to specifications and applications requested by customers.