Terahertz Imaging

Recently, electromagnetic radiation in the terahertz frequency range, best known as Terahertz radiation (hereafter abbreviated as THz), has emerged as one of the most promising measurement techniques for a variety of applications in science and engineering. THz, residing at a relatively unexplored region between the microwave and infrared, roughly 0.1-10THz, is one of the last frontiers in the electromagnetic spectrum. Unlike X-ray, THz causes no known harm to the human body and the materials being examined. THz can penetrate many common gases, non-polar liquids, and non-metallic solids including air, plastics, gasoline, paper, plant material, clothing, fatty tissue, and composites. Because they lie in a frequency region in which molecular resonances dominate, the absorption spectra of THz exhibit distinct signatures for substances such as water vapor, polar plastics, certain gases, DNA, crystalline solids, biofuel, and explosives. These advantages make THz a particularly attractive characterization tool in the areas of automotive, aviation, food, energy, materials, pharmaceuticals, medical diagnosis, forensics, defense, and homeland security. In fact, THz’s ability to penetrate thick foam-like materials has made it the de facto technique to inspect the foam insulation structures of NASA’s space shuttle fleet, the application that brought this technology to the interest of CNDE.

For the past five years, under the support of NASA, the Air Force, and the Army, CNDE has expanded its state-of-the-art modeling and processing capabilities further into THz technology. Significant progress had been made in addressing the inspection problem of the space shuttle’s external tank foam insulation as well as in providing assistance to Air Force Research Laboratory’s THz development. Elsewhere at ISU, faculty and researchers from various science and engineering disciplines have also quickly recognized the potential of THz technology. Driven by these needs, the acquisition of THz systems for imaging and spectroscopy was realized in 2008 via a major funding boost from the National Science Foundation’s Major Research Instrumentation program, and a new $0.5M THz research facility was established. With this new THz facility, a number of applications in physics, chemistry and engineering have been extensively studied, including the detection of chemical contamination in drinking water pipe systems, solvation of ionic liquids, fundamental studies of multiphase combustion and flow processes, and nondestructive evaluation of composite materials. The growing potential of THz has been further explored in inspecting many other advanced materials such as ceramic tiles and high-molecular weight fiber polymers used in military personal protection applications. It is evident that we have extended THz application opportunities well into the full spectrum of science and engineering disciplines with significant benefits in both research and education to the entire ISU community.

Research Highlights

Brief descriptions are given below to a few examples of recent research work conducted in the THz-FTIR facility.

Evaluation of Structural Integrity of Wind Turbines

The evaluation of the structural integrity of U.S. wind farm establishments has made considerable improvement by using state-of-the-art THz technology. CNDE recently conducted a promising feasibility study, signifying the superior capability of THz in determining the structural health of the turbine blades installed in massive windmills all around the nation.

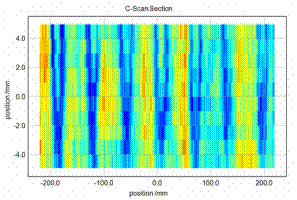

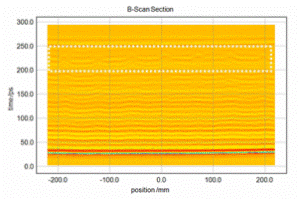

The energy generated from these wind farms has proven a viable source. Given the global fuel shortage and recent economic downturn, the demands for wind energy are growing fast. Consequently, assessing the structural integrity of the wind energy systems, particularly their key components of turbine blades, has also become a pressing issue in NDE. However, the structures of the turbine blades, consisting of complicated layers of mixed materials, have posed a difficult inspection problem to conventional NDE techniques. For instance, a wavy microstructure (“wrinkle”) embedded in the glass fiber-reinforced plastic (GFRP) laminates of the turbine blades represents a manufacturing anomaly. With its exceptional time and spatial resolutions, THz can reveal the wrinkles and quantify their aspect ratios precisely. This work not only pushes forward NDE research in general, but also contributes to the windpower industry in the home state of Iowa, which is a leading wind energy-producing state in the country.

(left) One of the Iowa wind farms; (right) THz imaging in action: a fiberglass laminate sample containing 7 simulated “wrinkles” is being scanned in reflection mode.

(left) C- and (right) B-scans clearly reveal the 7 “wrinkle” profiles (within the dashed box) in the fiberglass laminate.

Assessment of Chemical Contamination in Plastic Pipes of Water Distribution Systems

Plastic pipes such as polyvinyl chloride (PVC) and polyethylene (PE) are widely used in water distribution systems for the conveyance of drinking water. The longevity and structural integrity of the plastic pipes and the elastomeric gaskets for pipe joints are impacted by contaminated soils as a result of leaks from underground storage tanks, chemical spills, and improper disposal of used chemicals. Also of importance is the permeation of chemicals through the pipe materials or gaskets into the drinking water, which increases the health risk of consumers. Previous attempts to address these problems using NDE methods like near infrared have not been successful.

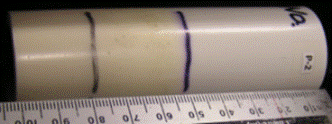

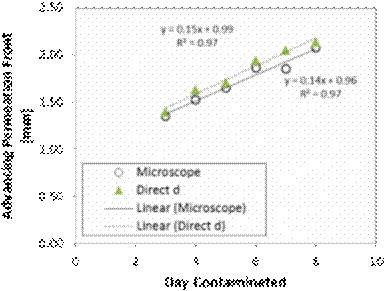

Recently CNDE, teaming up with Professor group in the Department of Civil, Construction and Environmental Engineering, demonstrated the feasibility of using THz to evaluate the physical condition and well-being of these plastic pipes. The preliminary results were quite encouraging. The research team was able to not only detect the presence of chemical contaminants, but also quantify the depth permeation into the pipe wall with high precision. This novel technique will have great impact on solving similar problems such as in the petroleum industry, where oil pipelines are increasingly replaced by polymeric composites.

(left) Contaminated (left half portion) PVC pipe sample, and (right) its image under THz.

The comparison of gasoline permeation advancing in the PVC pipe vs. days of contamination between THz detections (denoted as Direct d) and destructive sectioning examined under microscopy.

Fun Stuff

This section highlights some other fun things we have done with THz – with an eye on their potential applications in biomed, agriculture, food safety, quality control, ergonomics, and design cycle.

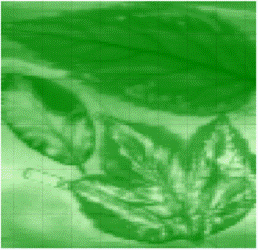

(left) Fresh autumn leaves taken outside the THz facility (shown with a 15-cm ruler) and (right) their corresponding images under THz. Can you spot a piece of plastic tape in the image?

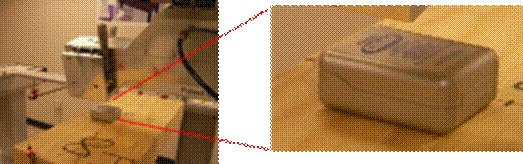

(top row) THz imaging of a floss box again demonstrates THz’s time-resolved ability to “peel” through the interior of a structure: (bottom row, left to right) top skin, below top skin and middle floss core.