Developments in digital radiographic inspection

In many cases a conventional radiographic inspection technique is used to control welding quality during the construction of cross-country pipelines. For large-diameter pipelines, battery-powered crawler systems are used, containing an X-ray tube that operates inside the pipeline. As a consequence, the pipeline sections must be limited in length to allow the deployment of a radiographic testing (RT) crawler system and to enable the regular recharging of batteries.

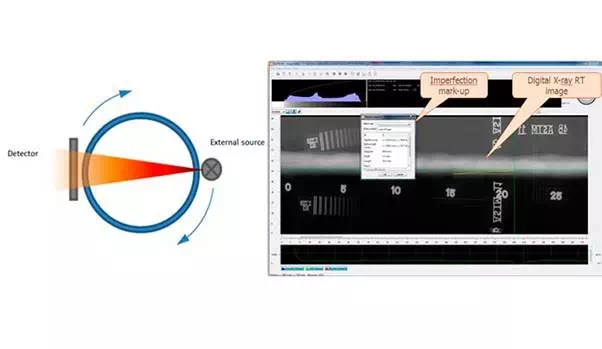

Working principle and digital radiograph image

Another aspect of using so-called “conventional RT” is the use of analogue film that needs to be processed at an external location. This is a time-consuming activity that means that, in most cases, the inspection results are only available the next day. Furthermore, due to radiation safety regulations, conventional RT inspection cannot be executed in the direct vicinity of welding or other activities, therefore inspection work must be carried out some way behind the mainline crew.

Digital radiography is a form of X-ray testing, where a digital X-ray sensor (detector) is used instead of traditional photographic film. Instead of strapping a film around the pipeline circumference, a detector and source X-ray are “rotated” around the pipe circumference using a non-destructive testing procedure in order to reconstruct a digital image and make it available as a digital file that can be presented for interpretation.

Applus+ RTD has already developed a high-quality digital radiographic inspectionsystem for mainly offshore applications. This system, known as “RTD Rayscan”, was developed for diameters up to 12” (30 cm) and primarily focused on stationary inspection applications such as lay barges.

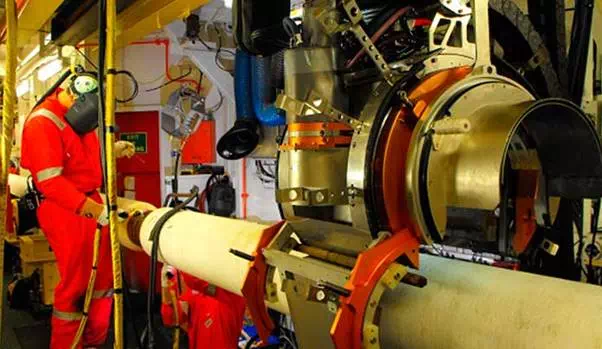

RTD Rayscan small bore system in use on a lay barge

The shielded Rayscan Oyster system has recently been introduced in the onshore new construction pipeline industry as Applus+ RTD’s next step in the development of digital radiographic inspection systems. This system allows the digital RT inspection of pipelines up to 36” (91 cm) and complies with the highest standards of digital radiographic image quality. This development was undertaken with the objective of reducing or even eliminating the traditional disadvantages of conventional RT on large-diameter pipelines.

Unlike conventional RT inspection, the shielded Rayscan Oyster system can operate in the near vicinity of the mainline welding crew during pipeline construction. This is possible since the Rayscan Oyster system is operated from a mobile, 4×4 truck and equipped with lead shielding against radiation. This shielding satisfies a maximum radiation dose rate of 7.5µSv/hr when a barrier distance of approximately 3 metres is applied.

Another advantage of the digital radiographic testing system is that the inspection results are available as soon as the scan is completed. This allows for their immediate interpretation and, therefore, the provision of direct, high-quality feedback to the applied welding process. This operational mode is similar to that of AUT inspection.

Rayscan Oyster system in use on cross-country pipeline

The shielded Rayscan Oyster system has the following features and specifications:

· Scanning speeds of up to 20 mm/s

· Can be safely used directly behind a welding crew

· Inspection of pipe-wall thicknesses of up to 35 mm (DWSI technique), fulfilling code and standard requirements

· High radiation-shielding options for safety purposes

· Immediate inspection results (digital film) after scanning is complete

· Digital storage of inspection results

· No chemicals or consumables (unlike with analogue film)

· No equipment in the pipe and no need for battery changes

· Reduced personnel costs (no darkroom technicians required)

With this innovation for large diameters, pipeline contractors can be far more flexible in the pipeline-construction process, can significantly reduce their operational costs and can operate under safer environmental and radiation conditions, using the shielded Rayscan Oyster digital radiographic inspection system to control the welding process.

The shielded Rayscan Oyster system was successfully used on its first commercial job in June 2016 in Kazakhstan. The system has received third-party qualification by Lloyds Register and is compliant with EN/ISO 17636-2:2013 (Class B) and ASME V article 2.