Material evaluation using Infrared “Active” Thermography

As further scientific advancements are made to the composition of the materials that are used to manufacture various components in the aerospace world, manufacturers are looking for more advanced inspection technologies that can offer reliable and repeatable inspection results in a cheaper, timelier manner.

In the past ultrasonic testing was the go to method of inspection for most of these types of applications; however over the years “Active” also known as “Pulsed” Thermography has emerged as a widely used and accepted form of inspection for material evaluation in non-destructive testing. Active Thermography is a non-contact form of NDT that can quickly provide valuable information regarding a material’s thermal properties, while also being able detect and characterize numerous types of subsurface flaws that may be present, as well as calculate the depth at which these flaws occur. Infrared Thermography has also been proven to accurately measure the thickness of critical areas located on a turbine blade or airfoil and can also measure the thickness of certain thermal barrier coatings that are applied to these parts during their final stages of manufacturing.

Infrared “Active” c Process

Active Thermography typically involves the use of an outside heat source to thermally excite the surface of a material; the surface of the material is then simultaneously observed as the heat diffuses from the surface of the part into the bulk of the material, using an Infrared Camera. Through this process, the thermal radiation emitted from the surface of the material can be evaluated for any indications or subsurface anomalies within that material. Indications or anomalies would then cause a disruption to the diffusion process and could be observed in a real-time evaluation or within a captured series of thermographic data. Thermography can be applied to a range of different material types, such as various metals and alloys, composites, polymers, and also ceramic materials.

The Equipment

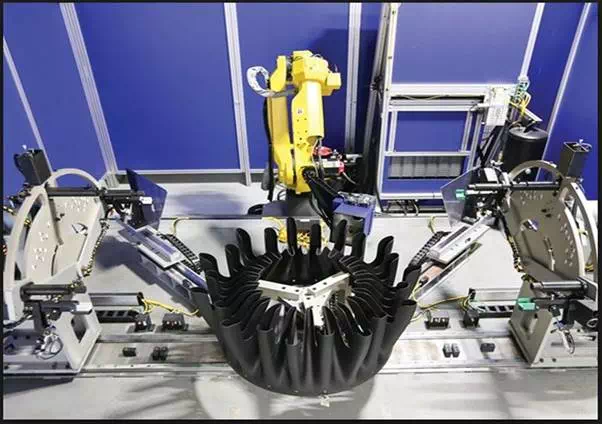

Applus+ has multiple Infrared Thermography Inspection systems which allow us to provide a wide range of inspection needs. In 2016, X-R-I Testing, an Applus+ company, successfully established a co-located operation with a customer in Covina, California, USA. We have acquired Prime approvals to use Active Thermography as the main inspection method for aerospace engine components, using a Robotic Infrared Inspection System. This Robotic Inspection System has the ability to inspect a range of components and can accommodate almost any geometric design. X-R-I Testing also has a separate gantry inspection system that can be easily modified and used as a portable inspection unit for field inspections. In addition, we have an Infrared Inspection System that specializes in turbine blade inspections, where the main focus is to inspect for blockages within the cooling channels, examine part thickness, and/or coating thickness.

Benefits of Infrared “Active” Thermography:

· Faster than all conventional NDT Methods

· Wide area of inspection

· Non-contact with material

· Equipment can be portable and can be easily implemented in field inspections

· Results can be easily interpreted

· Environmentally safe

Applications for Infrared “Active” Thermography:

· Delamination

· Adhesive disbonds

· Impact damage

· Corrosion

· Water entrapment

· Foreign Objet Debris (F.O.D) detection

· Thickness Measurement

· Porosity

· TBC coating measurement

· Crack detection

With the addition of Infrared Thermography, X-R-I Testing is now the first Prime approved Inspection Company that can offer this advanced NDT Method as a service to companies interested in utilizing this advanced technology. Take advantage of this high quality, cost effective solution today!