Geo-hazard Monitoring of Pipelines using Strain Gauges

Introduction

Pipelines are sometimes subjected to various geo-hazards such as long wall mining subsidence and slope movement. A commonly practiced method to reduce stress in such situations is to expose the affected portion of a pipeline. Monitoring of stress in an affected pipeline is a necessary component of a proper remedial plan. But strain gauges can only measure the changes in the strain with reference to the time of installation. An exposed pipeline has pre-existing stresses from differential temperature and internal pressure (‘pre-existing’ in the context of this note means stresses prior to the installation of strain gauges). ASME B31 limits are based on total and equivalent stress values. Therefore the pre-existing stresses and stress biaxiality (effect of hoop stress) should be included in the stress calculations.

The pre-existing stresses are usually estimated based on some simplifying assumptions and added to the measured stresses from strain gauges to calculate total stress. Pre-existing stresses from pressure are usually assumed to be tensile, while the thermal stresses are usually included only when they increase the total stresses. But these assumptions sometimes lead to complexities and confusion with unwanted consequences. In this article a common issue related to pipe internal pressure (and sometimes negative differential temperature) is discussed and methods to avoid it are explained.

Stress near Pipe Bends and Exposed Pipelines

Exposing a pipeline by excavating soil cover removes longitudinal and to some extent lateral restraints from around the pipe. As a result (with some exceptions) thermal stress due to positive temperature differentials between the time of pipeline installation and the time the monitoring is performed. This is because the pipeline can move sideways to release compression from a positive differential temperature that tends to elongate the pipe. Depending on the amount of sag in a pipeline a negative differential temperature may or may not create significant bending stress near pipe bends. Internal pressure, on the other hand, usually induces significant stress at and near bends of an exposed pipeline. Pressure tends to create tension in the longitudinal direction, creating an effect similar to that of a negative differential temperature. But internal pressure also acts on the pipe curvatures (thrust force and Bordon’s effect), and regardless of the amount of sag in a pipeline this effect can generate significant stress particularly along induction bends in a hilly terrain.

The Issue with Pre-Existing Stress Direction

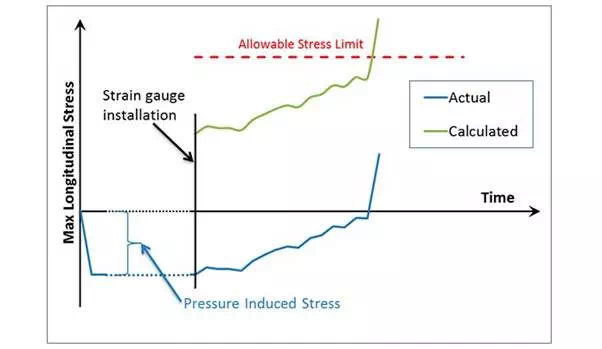

Pressure (or temperature) induced stresses near bends are primarily bending, and depending on the circumferential location, they can be compressive or tensile. The issue arises when the direction (tensile vs compressive) of the ground movement induced stress has an opposite sign to pre-existing stresses from pressure (or temperature), but the stress engineer, not knowing the actual stress, conservatively assumes that they have the same direction. The figure below schematically shows this problem.

In this figure the pre-existing stress from pressure at a gauge location is compressive while the ground induced stress has a tensile trend (and the opposite is true at the opposite clock position of the pipe cross-section). Therefore, the actual stress decreases with ground movement. But in the calculations the pre-existing stress is assumed to be tensile because the actual direction is unknown. As a result it appears as if the stress in the pipe is increasing. As the stress approaches the limit (red line) the operator may decide to shut in the pipeline, but to their surprise the stress appears to increase even higher when the pressure is reduced! The author has experienced this issue several times in actual monitoring projects where decreasing pipe pressure was associated with an apparent increase in the stress. The lesson is that the pre-existing stress should be determined realistically. As a minimum, an attempt should be made to predict the direction of pre-existing stresses.

Predicting Pre-Existing Stresses

One method to estimate pre-existing stresses is through finite element analysis (FEA) prior to strain gauge installation. Longitudinal stresses are very sensitive to actual sag in a pipeline, which usually cannot be determined easily. But a proper FEA can usually predict directions (tension versus compressive) of pre-existing stresses at various clock positions. A more direct method is to lower and then increase pipe internal pressure and monitor the gauges during the resulting pressure cycle. Then gauge responses can be extrapolated back to a zero pressure condition to determine pressure induced stresses. Due to potential interference of nonlinear effects, larger pressure cycles are preferred although practical restrictions may limit the amplitude of the pressure change. When construction documents of a pipeline contain ambient temperature records or at least construction season, a similar test can be performed on differential temperature, but this time more conveniently because every exposed pipeline experiences daily cycles of temperature. Therefore, normal operation does not need to be interrupted. All that is needed is a monitoring system which can measure and report pipe surface temperatures along with strains at an adequate frequency (e.g. every 30 minutes) throughout the day.

.