Gaseous Fuels

Gaseous Fuels and their types - The natural gas is, usually, found in or near the petroleum fields, under the earth's surface. It, essentially consists of marsh gas or methane (CH4) together with small amounts of other gases such as ethane (C2H6), carbon dioxide (CO2) and carbon monoxide (CO). The following prepared gases, which are used as fuels, are important:

1. Coal gas. It is also known as a town gas. It is obtained by the carbonisation of coal and consists mainly of Hydrogen, carbon monoxide and various hydrocarbons. It is very rich among combustible gases, and is largely used in towns for street and domestic lighting and heating. It is also used in furnaces and for running gas engines. Its calorific value is about 21000 to 25000 kJ / m3.

2. Producer gas. It is obtained by the partial combustion of coal, coke, anthracite coal or charcoal in a mixed air-steam blast. It is, mostly, used for furnaces particularly for glass melting and also for power generation. Its manufacturing cost is low, and has a calorific value of about 5000 to 6700 kJ / m3.

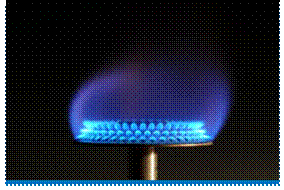

3. Water gas. It is a mixture of hydrogen and carbon monoxide and is made by passing steam over incandescent coke. As it burns with a blue flame, it is also known as blue water gas.

The water gas is usually converted into carburetted (enriched) water gas by passing it through a carburetor into which a gas oil is sprayed. It is, usually, mixed with coal gas to form town gas. The water gas is used in furnaces and for welding.

4. Mond gas. It is produced by passing air and a large amount of steam over waste coal at about 650° C. It is used for power generation and heating. It is also suitable for use in gas engines. Its calorific value is about 5850 kJ / m3.

5. Blast furnace gas. It is a by-product in the production of pig iron in the blast furnace. This gas serves as a fuel in steel works, for power generation in gas engines, for steam raising in boilers and for preheating the blast for furnace. It is extensively used as fuel for metallurgical furnaces. The gas, leaving the blast furnace, has a high dust content, the proportion of which varies with the operation of the furnace. It has a low heating value of about 3750 kJ / m3.

6. Coke oven gas. It is a by-product from coke oven, and is obtained by the carbonisation of bituminous coal. Its calorific value varies from 14500 to 18500 kJ / m3. It is used for industrial heating and power generation.