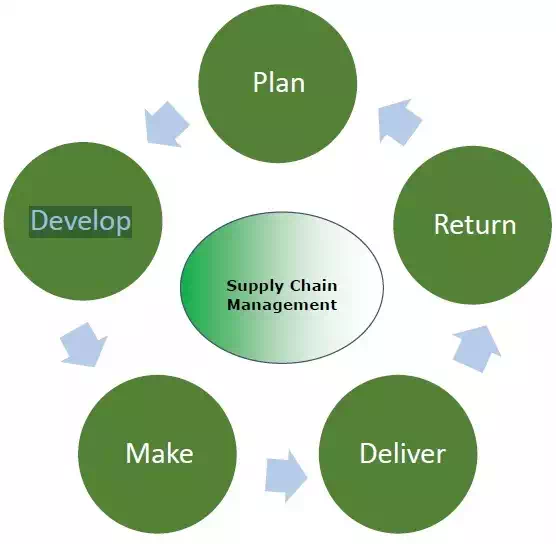

SCM - Process

Supply chain

management is a process used by companies to ensure that their supply chain is

efficient and cost-effective. A supply chain is the collection of steps that a

company takes to transform raw materials into a final product. The five basic

components of supply chain management are discussed below −

Plan

The initial stage

of the supply chain process is the planning stage. We need to develop a plan or

strategy in order to address how the products and services will satisfy the

demands and necessities of the customers. In this stage, the planning should

mainly focus on designing a strategy that yields maximum profit.

For managing all

the resources required for designing products and providing services, a strategy

has to be designed by the companies. Supply chain management mainly focuses on

planning and developing a set of metrics.

Develop(Source)

After planning,

the next step involves developing or sourcing. In this stage, we mainly

concentrate on building a strong relationship with suppliers of the raw

materials required for production. This involves not only identifying

dependable suppliers but also determining different planning methods for

shipping, delivery, and payment of the product.

Companies need to select

suppliers to deliver the items and services they require to develop their

product. So in this stage, the supply chain managers need to construct a set of

pricing, delivery and payment processes with suppliers and also create the

metrics for controlling and improving the relationships.

Finally, the

supply chain managers can combine all these processes for handling their goods

and services inventory. This handling comprises receiving and examining

shipments, transferring them to the manufacturing facilities and authorizing

supplier payments.

Make

The third step in

the supply chain management process is the manufacturing or making of products

that were demanded by the customer. In this stage, the products are designed,

produced, tested, packaged, and synchronized for delivery.

Here, the task of

the supply chain manager is to schedule all the activities required for

manufacturing, testing, packaging and preparation for delivery. This stage is

considered as the most metric-intensive unit of the supply chain, where firms

can gauge the quality levels, production output and worker productivity.

Deliver

The fourth stage

is the delivery stage. Here the products are delivered to the customer at the

destined location by the supplier. This stage is basically the logistics phase,

where customer orders are accepted and delivery of the goods is planned. The delivery

stage is often referred as logistics, where firms collaborate for the receipt

of orders from customers, establish a network of warehouses, pick carriers to

deliver products to customers and set up an invoicing system to receive

payments.

Return

The last and final

stage of supply chain management is referred as the return. In the stage,

defective or damaged goods are returned to the supplier by the customer. Here,

the companies need to deal with customer queries and respond to their

complaints etc.

This stage often

tends to be a problematic section of the supply chain for many companies. The

planners of supply chain need to discover a responsive and flexible network for

accepting damaged, defective and extra products back from their customers and

facilitating the return process for customers who have issues with delivered

products.