Synchronous Motor Working Principle

Electrical motor in general is an electro-mechanical

device that converts energy from electrical domain to mechanical domain. Based

on the type of input we have classified it into single phase and 3 phase

motors. Among 3 phase motors, induction motors and synchronous motors are more

widely used. When a 3 phase electric conductors are placed in a certain

geometrical positions (In certain angle from one another) then an electrical

field is generated. Now the rotating magnetic

field rotates at a certain speed, that speed is called

synchronous speed. Now if an electromagnet is present in this rotating magnetic

field, the electromagnet is magnetically locked with this rotating magnetic

field and rotates with same speed of rotating field.

Synchronous motors is called so because the speed of the rotor of this motor is

same as the rotating magnetic field. It is basically a fixed speed motor

because it has only one speed, which is synchronous speed and therefore no

intermediate speed is there or in other words itís in synchronism with the

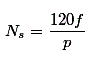

supply frequency. Synchronous speed is given by

where f

= supply frequency & p = no. of poles

Construction of Synchronous Motor

Normally it's construction

is almost similar to that of a 3 phase induction motor, except the fact that

the rotor is given DC supply, the reason of which is explained later. Now, let

us first go through the basic construction of this type of motor.

From the above picture, it is clear that how this type of motors are designed.

The stator is given is given three phase supply and the rotor is given dc supply.

Main Features of Synchronous Motors

1. Synchronous

motors are inherently not self-starting. They require some external means

to bring their speed close to synchronous speed to before they are synchronized.

2. The speed

of operation of is in synchronism with the supply frequency and hence for

constant supply frequency they behave as constant speed motor irrespective of

load condition

3. This motor

has the unique characteristics of operating under any electrical power

factor. This makes it being used in electrical power factor improvement.

Principle of Operation Synchronous Motor

Synchronous motor is a doubly excited machine i.e two

electrical inputs are provided to it. Itís stator winding

which consists of a 3 phase winding is provided with 3 phase supply and rotor

is provided with DC supply. The 3 phase stator winding carrying 3 phase

currents produces 3 phase rotating magnetic flux. The rotor carrying DC supply

also produces a constant flux. Considering the frequency to be 50 Hz, from the

above relation we can see that the 3 phase rotating flux rotates about 3000

revolution in 1 min or 50 revolutions in 1 sec. At a particular instant rotor

and stator poles might be of same polarity (N-N or S-S) causing repulsive force

on rotor and the very next second it will be N-S causing attractive force. But

due to inertia of the rotor, it is unable to rotate in any direction due to

attractive or repulsive force and remain in standstill condition. Hence it is

not self

starting.

To overcome this inertia, rotor is initially fed some mechanical input which

rotates it in same direction as magnetic field to a speed very close to

synchronous speed. After some time magnetic locking occurs and the synchronous

motor rotates in synchronism with the frequency.

Methods of Starting of Synchronous Motor

1. Motor

starting with an external prime Mover: Synchronous motors are

mechanically coupled with another motor. It could be either 3 phase induction

motor or DC shunt motor. DC excitation is not fed initially. It is

rotated at speed very close to its synchronous speed and after that DC

excitation is given. After some time when magnetic locking takes place supply

to the external motor is cut off.

2. Damper

winding: In case, synchronous motor is of salient pole type, additional

winding is placed in rotor pole face. Initially when rotor is standstill,

relative speed between damper winding and rotating air gap flux in large and

an emf is

induced in it which produces the required starting torque. As speed approaches

synchronous speed, emf and

torque is reduced and finally when magnetic locking takes place, torque also

reduces to zero. Hence in this case synchronous is first run as three

phase induction motor using additional winding and finally it is synchronized

with the frequency.

Application of Synchronous Motor

1. Synchronous

motor having no load connected to its shaft is used for power

factor improvement. Owing to its characteristics to behave at any

electrical power factor, it is used in power system in situations where

static capacitors are expensive.

2. Synchronous

motor finds application where operating speed is less (around 500 rpm) and high

power is required. For power requirement from 35 kW to 2500 KW, the size,

weight and cost of the corresponding three phase induction motor is very high.

Hence these motors are preferably used. Ex- Reciprocating pump, compressor,

rolling mills etc.