Variable Frequency Drive or VFD

It is

interesting to know that the first A.C. drive (400 HP) based on thyratron cycloconverter-fed

WRIM was installed in 1932 by F.E. Alexanderson of General Electric in the

Logan Power Station of Pacific Gas and Electric Company. From then industrial

drives have evolved rapidly by dedicated effort of many scientists and

engineers all over the world resulting in development of advanced drive

technology such as Variable Frequency Drive(VFD).VFD is a power

electronics based device which converts a basic fixed frequency, fixed voltage sine wave power (line

power) to a variable frequency, variable output voltage used to control speed

of induction motor(s). It regulates the speed of a three phase induction motor by controlling the

frequency and voltage of the power supplied to the motor.

Since the number of pole is constant the speed Ns can be varied

by continuously changing frequency.

Working of Variable Frequency Drive

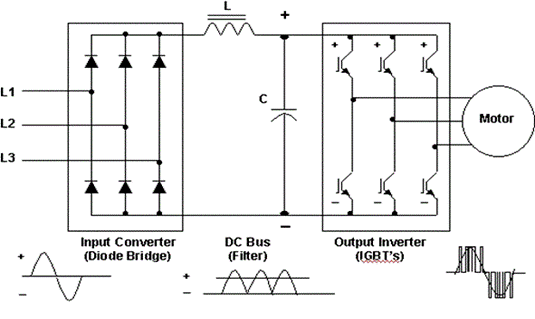

Any Variable

Frequency Drive or VFD incorporates following three stages for controlling a

three phase induction motor.

Rectifier

Stage

A full-wave

power diode based solid-state

rectifier converts three-phase 50 Hz power from a standard 220, 440 or higher

utility supply to either fixed or adjustable DC voltage. The system may include

transformers for high voltage system.

Inverter

Stage

Power electronic

switches such as IGBT, GTO or SCR switch

the DC power from rectifier on and off to produce a current or voltage waveform

at the required new frequency. Presently most of the voltage source inverters (VSI) use

pulse width modulation (PWM) because the current and voltage waveform at output in this scheme is

approximately a sine wave. Power Electronic switches such as IGBT; GTO etc.

switch DC voltage at high speed, producing a series of short-width pulses of

constant amplitude. Output voltage is varied by varying the gain of the

inverter. Output frequency is adjusted by changing the number of pulses per

half cycle or by varying the period for each time cycle.

The resulting current in an induction motor simulates a sine wave of the desired output frequency. The

high speed switching action of a PWM inverter results in less waveform

distortion and hence decreases harmonic losses.

Control

System

Its function is

to control output voltage i.e. voltage vector of inverter being fed to motor

and maintain a constant ratio of voltage to frequency (V/Hz). It consists of an

electronic circuit which receives feedback information from the driven motor

and adjusts the output voltage or frequency to the desired values. Control

system may be based on SPWM (Sine Wave PWM), SVPWM (Space Vector modulated PWM)

or some soft computing based algorithm.

Induction

Motor Characteristic under Variable Frequency Drive

In an

induction motor induced in

stator, E is proportional to the product of the slip frequency and the air gap

flux. The terminal voltage can be considered proportional to the product of the

slip frequency and flux, if stator drop is neglected. Any reduction in the supply

frequency without a change in the terminal voltage causes an increase in the

air gap flux which will cause magnetic saturation of motor. Also the torque capability of motor is

decreased. Hence while controlling a motor with the help of VFD or Variable

Frequency Drive we always keep the V/f ratio constant.

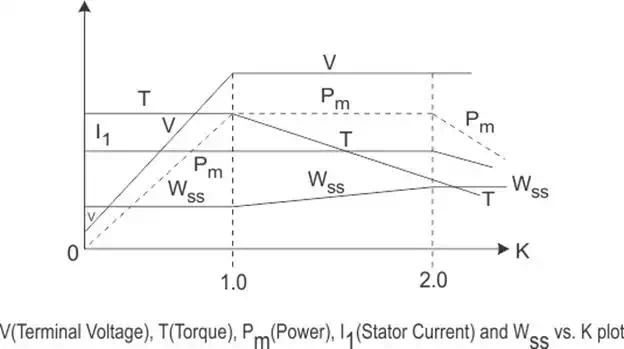

Now define variable ‘K’ as,

For operation below K < 1 i.e. below rated frequency we have constant flux operation.

For this we maintain constant magnetization current Im for all

operating points.

For K > 1 i.e. above rated frequency we maintain terminal voltage Vrated constant.

In this field is weakened in the inverse ratio of per unit frequency ‘K’.

For values of K = 1 we have constant torque operation and above that we have

constant power application.

Merits of using Variable Frequency Drives

Primary function

of VFD in industry is to provide smooth control along with energy savings. The

variable speed motor drive system is more efficient than all other flow control

methods including valves, turbines, hydraulic transmissions, dampers, etc.

Energy cost savings becomes more pronounced in variable-torque ID fan and pump

applications, where the load’s torque and power is directly proportional to the

square and cube of the speed respectively.

Increased

Reliability

Adjustable speed

motor-drive systems are more reliable than traditional mechanical approaches

such as using valves, gears, louvers or turbines to control speed and flow.

Unlike mechanical control system they don’t have any moving parts hence they

are highly reliable.

Speed Variations

Beyond energy

saving, applications such as crushers, conveyors and grinding mills can use the

motor and VFD’s packages to provide optimal speed variations. In some crucial

applications, the operating speed range can be wide, which a motor supplied

with a constant frequency power source cannot provide. In the case of conveyors

and mills, a VFD and motor system can even provide a “crawl” speed foe

maintenance purposes eliminating the need for additional drives.

Soft Starting

When Variable

Frequency Drives start large motors, the drawbacks associated with large inrush

current i.e. starting current (winding stress, winding overheating and voltage

dip on connected bus) is eliminated. This reduces chances of insulation or

winding damage and provides extended motor life.

Extended Machine Life and Less

Maintenance

The VFD’s

greatly reduce wear to the motor, increase life of the equipment and decrease

maintenance costs. Due to optimal voltage and frequency control it offers

better protection to the motor from issues such as electro thermal overloads,

phase faults, over voltage, under voltage etc. When we start a motor (on load)

with help of a VFD, the motor is not subjected to “instant shock” hence there

is less wear and tear of belt, gear and pulley system.

High Power Factor

Power converted

to rotation, heat, sound, etc. is called active power and is measured in

kilowatts (kW). Power that charges builds magnetic fields or charges capacitor is called reactive

power and is measured in kVAR.

The vector sum of the kW and the kVAR is the Apparent

Power and is measured in KVA. Power factor is the ratio of kW/KVA. Typical AC

motors may have a full load power factor ranging from 0.7 to 0.8. As the motor load is reduced, the

power factor becomes low. The advantage of using VFD’s is that it includes

capacitors in the DC Bus itself which maintains high power factor on the line

side of the Variable Frequency Drive. This eliminates the need of additional

expensive capacitor banks.

Slip

Power Recovery

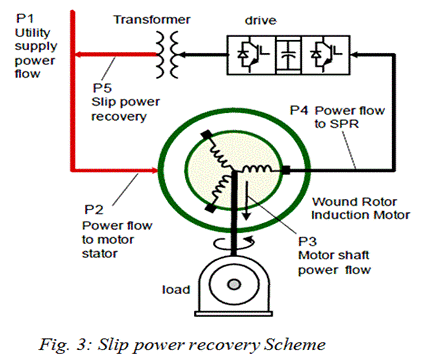

The fundamental

power given to rotor by stator is called air gap power Pg. The mechanical

power developed is given by

The term 'sP' is

called slip power.

If the slip is very large i.e. speed is low then there is ample waste of power,

a common example is kiln drives of cement industry. This power can be saved

through slip recovery scheme.In this

scheme slip power is first collected through brushes of WRIM. This slip power

recovered is then rectified and inverted back to line frequency and is injected

into supply through coupling transformer.The scheme is shown in figure

below.

Applications

of Variable Frequency Drive

1. They are mostly used in

industries for large induction motor (dealing with variable load) whose power rating ranges

from few kW to few MW.

2. Variable Frequency Drive is

used in traction system. In India it is being used by Delhi Metro Rail

Corporation.

3. They are also used in

modern lifts, escalators and pumping systems.

4. Nowadays they are being

also used in energy efficient refrigerators, AC’s and Outside-air Economizers.