Stepper

motors are

available in three basic configurations:

1. Universal

Stepper Motor-

A universal stepper motor can be connected as a bipolar or a uni-polar

stepper motor.

2. Uni-polar

Stepper Motor-

A Uni-polar

stepper motor can be used as uni-polar or a bipolar stepper motor.

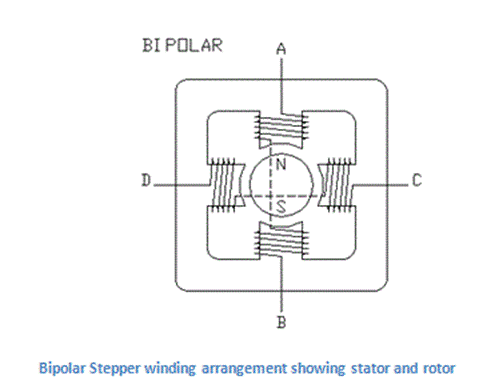

3. Bipolar

stepper Motor-

A bipolar stepper motor can only be used as a bipolar.

A bipolar

stepper motor has one winding per stator phase. A two phase bipolar stepper

motor will have 4 leads. In a bipolar stepper we donít have a common lead like

in a uni-polar

stepper motor. Hence, there is no natural reversal of current direction through the

winding.

A bipolar stepper motor has easy wiring arrangement but its operation is little

complex. In order to drive a bipolar stepper, we need a driver IC with an internal H

bridge circuit. This is because, in order to reverse the polarity of stator

poles, the current needs to be reversed. This can only be done through a H

bridge.

There are two

other reasons to use an H Bridge IC

1. The current draw of a

stepper motor is quite high. The micro-controller pin can only provide up to 15

mA at maximum. The stepper needs current which is around ten times this

value. A external

driver IC is capable of handling such high currents.

2. Another reason why H Bridge

is used is because the stator coils are nothing but inductor. When coil current changes

direction a spike is generated. A normal micro-controller pin cannot tolerate

such high spikes without damaging itself. Hence to protect micro-controller

pins, H bridgeis

necessary.

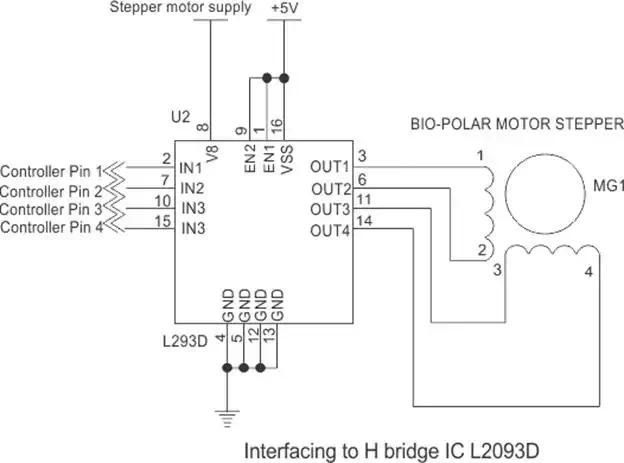

The most common H Bridge IC used in most Bipolar stepper interfacing projects

is L293D.

Interfacing to Micro-Controller

4

micro-controller pins are required to control the motor. We need to provide the

L293D with 5 V supply as well as the voltage at which the motor needs to operate. Since we will be

using both the drivers of the IC, we will assert the enable pin for both of

them.

Interfacing Diagram

There are

three different ways in which we can drive the bipolar stepper motor-

1. Only one of the phase

winding are energized at a time. That is, either AB or CD is energized. Of

course the coils will be energized in such a way that we get correct polarity.

But only one phase is energized. This type of stepping will give less holding

torque because only one phase is energized.

2. In this method, both the

phases are activated at the same time. The rotor will align itself between two

poles. This arrangement will give higher holding torque than the previous

method.

3. The third method is used

for half stepping. This method is used generally to improve the stepping angle.

Here, in step 1 only 1 phase is ON, then in step 2, 2 phases are ON, then again

only one phase is ON and the sequence continues.

Many companies

have started assembling their own bipolar stepper drives. Care must be taken

that you connect the stepper motor correctly to the drive. Also the drive must

be able to supply sufficient current for you stepper. The micro-controller must

only provide the step and direction signal to the drive. This method will

occupy only two micro-controller pins and is very helpful in projects that

require large number of micro-controller pins for other functions.

Unipolar Stepper v/s Bipolar Stepper

Both uni-polar

and Bipolar steppers

are used widely in projects. However, they have their own advantages and

disadvantages from the application point of view. The advantage of a uni-polar

motor is that we do not have to use a complex H bridge circuitry to control the

stepper motor. Only a simple driver like ULN2003A will do the task

satisfactorily. But, there is one disadvantage of uni-polar motors. The

torque generated by them is quite less. This is because the current is flowing

only through the half the winding. Hence they are used in low torque

applications.

On the other hand, bipolar stepper motors are a little complex to wire as we

have to use a current reversing H bridge driver IC like an L293D. But the

advantage is that the current will flow through the full coil. The resulting

torque generated by the motor is larger as compared to a uni-polar

motor.