Synchronous Motor Drives

As the name

suggests the synchronous

motors rotates

at synchronous speed. The main advantage of synchronous motors are that they

run on 3 AC supply and DC supply is given to the rotor when they run on

synchronous speed the loss is very minimal. We can say that if the synchronous

motors are designed to run only at rated synchronous speeds, then what is the use of

introducing drives to them. The answer is pretty simple,

synchronous motor drives makes the starting, pull in and braking process smooth and

without any problems. We shall discuss about them one by one.

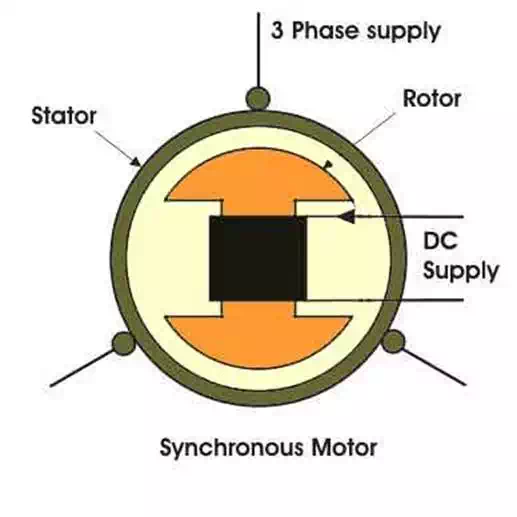

Starting Synchronous Motors

The problem with

synchronous motors are that they are not self- starting. Before discussing the

starting method of this motor, we should know about the type of supply and the

rotor and the stator of the motor briefly.

The stator of synchronous motors are similar to that of an induction motors but the only

difference lies in the rotor, the rotor of the synchronous motors are given dc

supply.

Now before knowing, how the synchronous motors are started, we should know why

they are not self

started? The answer can be given as, when 3 phase supply is given

to the stator, there is a rotating magnetic flux which rotates at synchronous speed, and if the rotor is

also given DC supply, rotor acts as a magnetic flux which rotates at

synchronous speed, and if the rotor is also given dc supply, rotor acts as a

magnet having two salient poles. As the rotor is at standstill position, it

cannot follow the magnetic field which is rotating at synchronous speed. The rotor stacks

at its position because the opposite poles move so rapidly that the rotor

locks, this is the reason why synchronous motors are not self starting.

Now coming to the point how synchronous motors are started. At first the

synchronous motors are started as a normal induction motors, the rotor of the

motor is not given dc supply, when the motor reaches the rotor and pull in

takes place, which is discussed later.

Another method

of starting the synchronous motor drives is by external motor. In this method

the rotor of the synchronous motor is rotated by an external motor and when the

speed of the rotor reaches near synchronous speed, the DC-field is switched on

and pull in takes place. In this method, the starting torque is very low and it

is not very popular method also.

Pull

in of Synchronous Motors

When the rotor

of the synchronous motors reaches near synchronous speed, then the DC field

supply is switched on and the pull in process begins. As during switching on

the DC supply due to the phase angle and torque angle there are various

disturbances seen in the motor and there are several slip of poles of air-gap

flux is also seen. As the pull in process is completed the rotor acquires

synchronous speed. The complete pull in as fast as possible the DC supply

should be switched on at the most favorable angle. Like

when the synchronous motor is running as induction motor, the DC supply should

be fed when the induction motor is at top speed, this will be the best moment

because the speed difference will be least at that point of time.

Braking of Synchronous Motors

As we know,

there are three types of braking i.e, regenerative, dynamic

and plugging type braking. But for synchronous motor drives only dynamic braking can be applied though

plugging can be applied theoretically. Regenerative braking cannot be applied

to them as they need higher speed than synchronous speed. Dynamic braking is

done by disconnecting the motor from supply and connecting it across a three

phase resistor. At that time the motor

works as a synchronous

generator and

energy is dissipated at the resistors. Plugging is not used for synchronous

motors as high plugging current can cause severe disturbance and damage in line.