Control of Electrical Drives

Electrical

drives have

become the most essential equipment now days in the electrical motors and other rotating

machines. We know that electrical drives mainly accomplishes three kinds of

work,

1. Starting

2. Speed control

3. Braking

It can be said that the electrical drives enable us to control the motor in

every aspect. But control of electrical drives is also necessary because all

the functions accomplished by the drives are mainly transient operations i.e the

change in terminal voltage, current, etc are huge which may

damage the motor temporarily or permanently. That’s why the need of controlling

the drives rises and there are various methods and equipment's to control

different parameters of the drives which are discussed later.

In a control

system, there are two types of systems, one is open loop and the other is closed loop control system. In open loop control

system the output has no effect on the input, i.e the controlling

phenomenon is independent of the output, on the other hand closed loop control system is much more advanced

and scientific, here the output is fed back to the input terminal which

determines the amount of input to the system, for example if the output is more

than predetermined value the input is reduced and vice-versa. In electrical drives feedback loops

or closed

loop control satisfy

the following requirements.

1. Protection

2. Enhancement of speed of

response

3. To improve steady –state

accuracy

In the following discussions, we will see through different closed loop

configurations which are used in electrical drives irrespective of the type of supply they are fed, i.e DC

or AC.

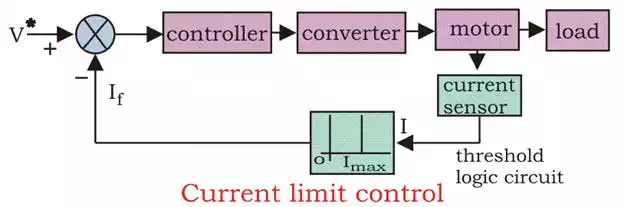

Current Limit Control

During the

starting, we know if precautionary measures are not taken there is a chance of

huge current flow through the

motor circuit. To limit the current and sense the current fed to the motor, current limit

controller is installed. The feedback loop does not effect the normal

operation of the drive but if the current exceeds the predetermined safe limit,

the feedback loop activates and the current is brought down below the safe

limit. Once the current is brought down below the safe limit the feedback loop

again deactivates and in this way the control of current takes place.

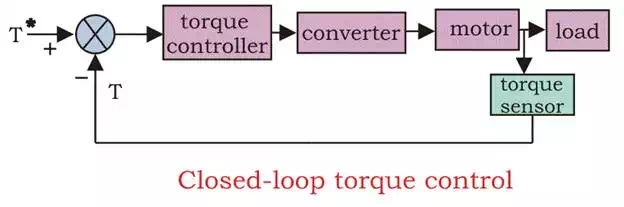

Closed Loop Torque Control

This type of

torque controller is seen mainly in battery operated vehicles like cars,

trains etc. the accelerator present in the vehicles is pressed by the driver to

set the reference torque T. The actual torque T follows the T* which

is controlled by the driver via accelerator.

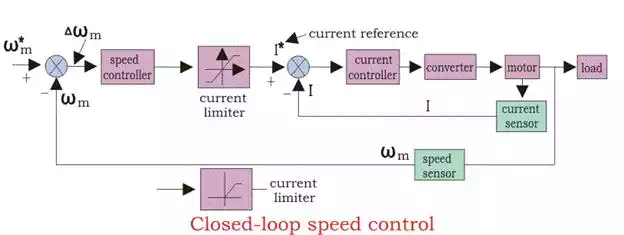

Closed Loop Speed Control

Speed control

loops are perhaps the most widely used feedback loops for drives. If we first

see the block diagram of this loop then it will be a lot easier for us to

understand.

We can see from the diagram that there are two control loops, which can be said

as an inner loop and outer loop. The inner current control loop limits the converter and motor current or

motor torque below the safe limit. Now we can understand the function of the

control loop and drive by practical examples. Suppose the reference speed Wm* increases

and there is a positive error ΔWm, which indicates that the

speed is needed to be increased.

Now the inner

loop increases the current keeping it under maximum allowable current. And then

the driver accelerates, when the speed reaches the desired speed then the motor

torque is equal to the load torque and there is a decrease in the reference

speed Wm which indicates that there is no need of any more acceleration but

there must be deceleration, and braking is done by the speed controller at

maximum allowable current. So, we can say that during speed controlling the

function transfers from motoring to braking and from braking to motoring

continuously for the smooth operation and running of the motor.