Induction Motor Braking Regenerative Plugging Dynamic Braking of

Induction Motor

Induction motors are used at various

places. Speed control of induction motors is quite difficult and that’s why

their use was restricted and DC motors had to be used as their speed regulation was possible. But

when induction motor drives were invented and implemented, they were given

preference because of many advantages over DC motors. Whenever controlling of

motors is done, braking is the most important term, so as with induction

motors. Induction motor braking can be done by different methods, which are-

1. Regenerative braking of

induction motor

2. Plugging Braking of

induction motor

3. Dynamic braking of

induction motoris further

categorized as

● AC dynamic breaking

● Self

excited braking

using capacitors

● DC dynamic braking

● Zero Sequence braking

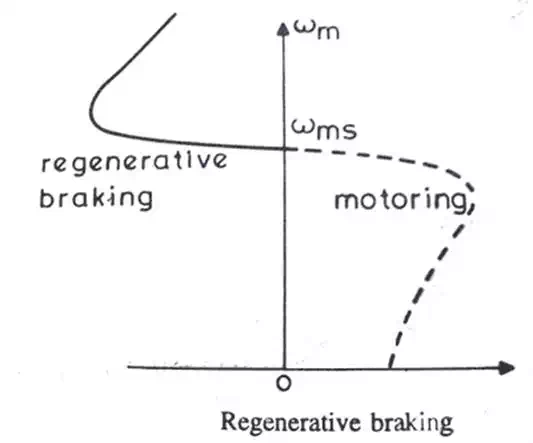

Regenerative Braking of Induction Motor

We know

the power (input) of an induction motor is given as.

Pin =

3VIscosφs

Here, φs the phase angle

between stator phase voltage V and the stator phase current Is. Now, for motoring

operation φs < 90° and for

braking operation φs > 90°. When the

speed of the motor is more than the synchronous speed, relative speed between

the motor conductors and air gap rotating

field reverses, as a result the phase angle because greater than 90° and the

power flow reverse and thus regenerative braking takes place. The nature of the

speed torque curves are shown in the figure beside. It the source frequency is

fixed then the regenerative braking of induction motor can only take place if

the speed of the motor is greater than synchronous speed, but with a variable

frequency source regenerative braking of induction motor can occur for speeds

lower than synchronous speed. The main advantage of this kind of braking can be

said that the generated power is use fully employed and the main disadvantage of

this type of braking is that for fixed frequency sources, braking cannot happen

below synchronous speeds.

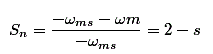

Plugging Braking of Induction Motor

Plugging

induction motor braking is done by reversing the phase sequence of the motor.

Plugging braking of induction motor is done by interchanging connections of any

two phases of stator with respect of supply terminals. And with that the

operation of motoring shifts to plugging braking. During plugging the slip is

(2 - s), if the original slip of the running motor is s, then it can be shown

in the following way.

From the figure beside we can see that the torque is not zero at zero speed.

That’s why when the motor is needed to be stopped, it should be disconnected

from the supply at near zero speed. The motor is connected to rotate in the

reverse direction and the torque is not zero at zero or any other speed, and as

a result the motor first decelerates to zero and then smoothly accelerates in

the opposite direction.

Dynamic Braking of Induction Motor

There are four

type of dynamic braking of induction motor or rheostatic braking, we

will discuss about then.

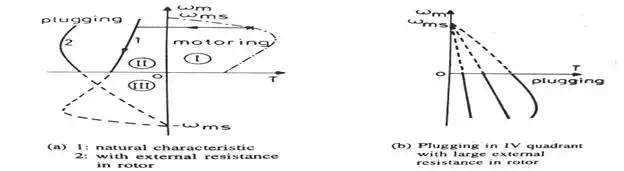

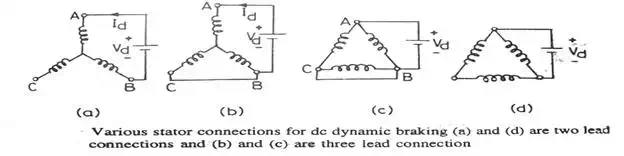

AC Dynamic Braking-

This type of induction motor braking is obtained when the motor is made to run

on a single phase supply by disconnecting any one of the three phase from the

source, and it is either left open or it is connected with another phase. When

the disconnected phase is left open, it is called two lead connection and when

the disconnected phase is connected to another machine phase it is known as

three load connection. The braking operation can be understood easily. When the

motor is running on 1-phase supply, the motor is fed by positive and negative

sequence, net torque produced by the machine at that point of time is sum of torques

due to positive and negative sequence voltage. At high resistance the net torque is

found to be negative and braking occurs. From the figure below the two and

three load connections can be understood.

Self excited braking using capacitors

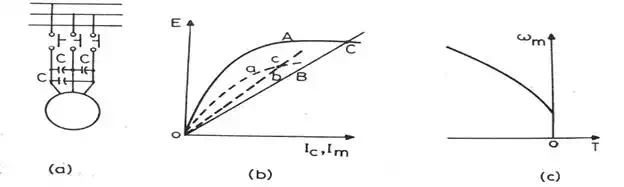

The figures

above shows the circuit diagram and various characteristics of self excited braking

using capacitors. As we can see from the figure, in this method there

capacitors are kept permanently connected across the source terminals of the

motor. The value of the capacitors are chosen depending upon their capability

to deliver enough reactive current to excite the motor and make it work as a

generator. So, that when the motor terminals are disconnected from the source

the motor works as a self

excited generator and the produced torque and field is in

the opposite direction and the induction motor braking operation occurs. In the

figure (b) the curve A represents the no load magnetization curve and line B is

the current through capacitors, which is given by

Here, E is the stator induced voltage per phase

The speed torque characteristics under self excited braking is

shown in the figure (c). To increase the braking torque and to utilize the

generated energy sometimes external electrical resistance are connected across the stator terminals.

DC Dynamic Braking

To obtain

this type

of braking the

stator of a running induction motor is connected to a DC supply. Two and three

load connections are the two common type of connections for star and delta

connected stators.

Another diagram

is shown below to illustrate how by diode bridge two load coonection can

be obtained within a circuit.

Two Loads DC Dynamic Braking Operation

Now coming to the method of operation, the moment when AC supply is

disconnected and DC supply is introduced across the terminals of the induction

motor, there is a stationery magnetic field generated due to the DC current flow and as the rotor of

the motor rotates in that field, there is a field induces in the rotor winding,

and as a result the machine works as a generator and the generated energy

dissipates in the rotor circuit resistance and dynamic braking of induction

motor occurs.

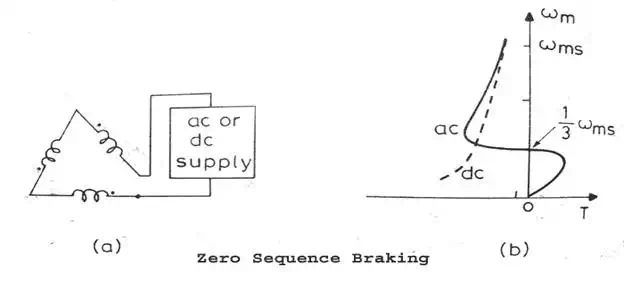

Zero

Sequence Braking

In this type of braking all the three stator phases are connected in series and

single phase AC or DC is connected across them (as shown in the figure). This

type of connection is called zero-sequence connection, because current in all

the stator windings are co-phasal.

When the connected supply is AC, resultant field is stationery in space and

pulsates at the frequency of supply, when the supply is DC, resultant field is

stationery and is of constant magnitude. The main advantage of this induction

motor braking is that all the stator phases are uniformly loaded. It does not

require large rotor resistance like AC dynamic braking, it does not require

large rotor resistance. The circuit diagram and the speed torque

characteristics are shown below.

The above discussion easily describes the concept of induction motor breaking.