What is Electrical Drive?

Whenever the

term electric motor or electrical generator is used, we tend to think that the

speed of rotation of these machines is totally controlled only by the

applied voltage and frequency of the

source current. But the speed of rotation of an electrical machine can be

controlled precisely also by implementing the concept of drive. The main

advantage of this concept is, the motion control is easily optimized with the

help of drive.

In very

simple words, the systems which control the motion of the electrical machines,

are known as electrical drives. A typical drive system is assembled with a electric motor (may be several) and

a sophisticated control system that controls the rotation of the motor shaft.

Now days, this control can be done easily with the help of software. So, the

controlling becomes more and more accurate and this concept of drive also

provides the ease of use. This drive system is widely used in large number of

industrial and domestic applications like factories,

transportation systems, textile mills, fans, pumps, motors, robots etc. Drives

are employed as prime movers for diesel or petrol engines, gas or steam turbines, hydraulic

motors and electric

motors.

Now coming to the history of electrical drives, this was first designed in

Russia in the year 1838 by B.S.Iakobi, when he tested a DC electric motor supplied from a

storage battery and propelled a boat. Even though the industrial

adaptation occurred after many years as around 1870. Today almost everywhere

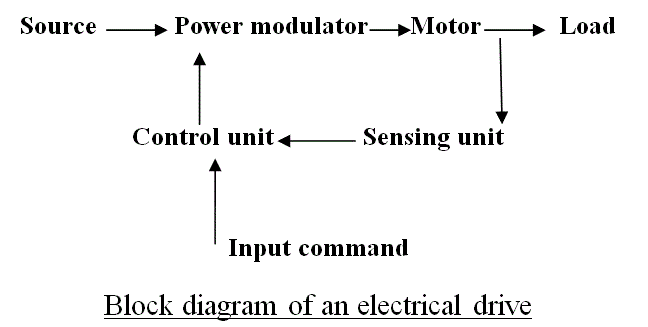

the application of electric drives is seen. The very basic block diagram an

electric drives is shown below. The load in the figure represents various types

of equipments which

consists of electric

motor, like

fans, pumps, washing machines etc.