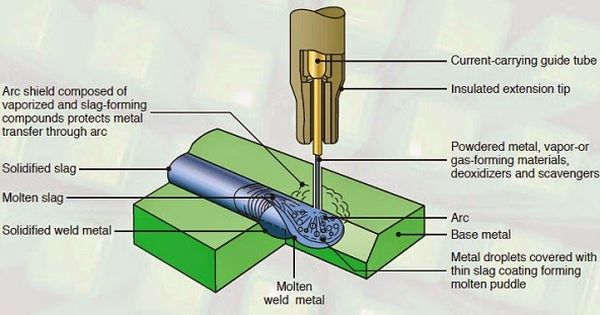

Flux-cored Arc Welding (FCAW)

The flux-cored arc welding process is shown in image below is similar to Gas Metal-arc Welding, except that the electrode is tubular in shape and is filled with flux. Cored electrodes produce a more stable arc, improve weld contour and produce better mechanical properties of the weld metal. The flux in these electrodes is much more flexible than the brittle coating used on Shielded Metal-arc Welding electrodes, so the tubular electrode can be provided in long coiled lengths.

Schematic illustration of the flux-cored arc-welding process.

The electrodes used in this welding process are usually 0.5 mm to 4 mm in diameter and the power required is about 20 kW. Self-shielded cored electrodes also are available. They do not require any external shielding gas, because they contain emissive fluxes that shield the weld area against the surrounding atmosphere. Small diameter electrodes have made the welding of thinner materials not only possible but often preferable for using. Also small diameter electrodes make it relatively easy to weld joints in different positions and the flux chemistry permits the welding of many metals.

The Flux-cored arc Welding process combines the versatility of Shielded Metal arc welding with the continuous and automatic electrode feeding feature of gas metal-arc welding. The process is economical and versatile, so it is used for welding a variety of joints, mainly on steels, stainless steels, and nickel alloys. The higher weld metal deposition rate of the flux-cored arc welding process has led to its use in the joining of sections of all thicknesses. The use of tubular electrodes with very small diameters has extended the use of this process to work pieces of smaller section size.

A main advantage of using flux-cored arc welding is the ease with which specific weld-metal things can be developed. By adding alloying elements to the flux core, virtually any alloy composition can be produced. The process is easy to automate and is readily adaptable to flexible manufacturing systems and robotics.