In

Plasma-arc Welding (PAW) is an arc welding process, a concentrated plasma arc

is produced and directed towards the weld area. The arc is stable and reaches

temperatures as high as 33,000°C. A plasma is an ionised very hot gas composed

of nearly same numbers of electrons and ions. The plasma starts between the

tungsten electrode and the orifice by a low current pilot arc. What makes

plasma-arc welding unlike other processes is that the plasma arc is

concentrated because it is forced through a relatively small orifice. Operating

currents usually are less than 100 A. When a filler metal is used it is fed

into the arc as is done in Gas Tungsten-arc Welding. Arc and weld-zone

shielding is supplied by means of an outer-shielding ring and the use of inert

gases like argon, helium or mixtures.

There are two methods of plasma-arc

welding:

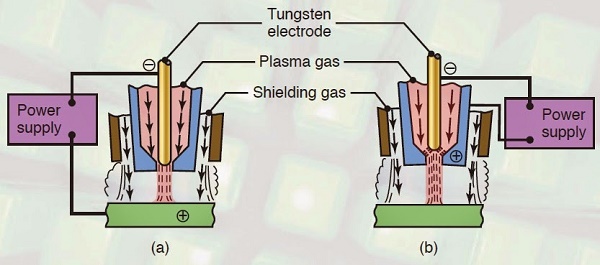

§ In the

transferred-arc method of plasma-arc welding(in pic left side),

the workpiece being welded is part of the electrical

circuit. The arc transfers from the electrode to the work

piece hence the term transferred.

§ In the non transferred-arc

method of plasma-arc welding(in

pic right side), the arc occurs between the electrode and the nozzle and the

heat is carried to the workpiece by the plasma gas. This thermal-transfer

mechanism is similar to that for an oxy-fuel flame.

Two

methods of plasma-arc welding processes (a) transferred and (b) non transferred

Compared

to other arc welding processes, Plasma-arc Welding process has better arc

stability, less thermal distortion and higher energy concentration, thus

permitting deeper and narrower welds. PAW has higher welding speed ranges from

120 mm/min to 1000 mm/min. A variety of metals can be welded with part

thicknesses less than 6 mm.

The high heat concentration can penetrate completely through the joint with

thicknesses as much as 20 mm for some titanium and aluminium alloys. In the

keyhole technique, the force of the plasma arc displaces the molten metal and

produces a hole at the leading edge of the weld pool. Plasma-arc welding often

is used rather than Gas Tungsten-arc welding for butt and lap joints because of

its higher energy concentration, better arc stability and higher speed of

welding. Proper training and skill are required for operator who works on this

equipment.