Gas Tungsten-arc Welding (GTAW)

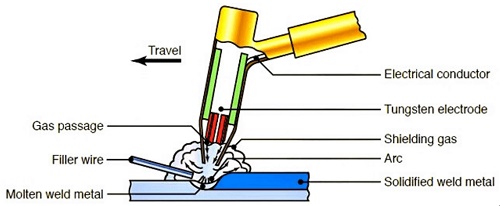

Gas Tungsten-arc Welding (GTAW) formerly known as TIG (Tungsten

Inert Gas) welding, the filler metal is supplied from a filler wire as

shown in the figure below. The tungsten electrode is not used during this

welding operation, a constant and stable arc gap is maintained at a constant

current level. The filler metals are similar to the metals to be welded and

flux is not used. The shielding gas used in this welding process is usually

argon or helium (or a mixture of these both gases). Welding with gas

tungsten-arc welding may be done without using filler metals. for example,

in the welding of close-fit joints.

Schematic

diagram of Gas Tungsten-arc welding process

Depending on the type of metals to be welded, the power supply

is either DC at 200A or AC at 500A (see below image). In general, AC is

preferred for welding metals aluminium and magnesium, because the cleaning

action of AC removes oxides and improves weld quality. Thorium or zirconium can

be used in the tungsten electrodes to improve their electron emission

characteristics. The power supply ranges from 8 to 20 kW. Contamination of the

tungsten electrode by the molten metal can be a major problem, particularly in

critical applications, because it can cause discontinuities in the weld.

Contact of the electrode with the molten-metal pool should be avoided.

Equipments used for gas

tungsten-arc welding operations

The gas tungsten-arc welding process is used for a wide variety

of applications and metals, particularly aluminium, magnesium, titanium and the

refractory metals. It is highly suitable for thin metals. The cost of the inert

gas makes this process more expensive than Shielded Metal-arc

Welding but provides welds of very high quality and surface finish.

The equipment

used for gas tungsten-arc welding process is portable.

Applications of Gas

Tungsten-arc Welding:

§ Originally

developed for welding Aluminium and Magnesium.

§ The other metals

are Stainless steel, High carbon steel, Copper, Monel(Ni + Cu+ Fe +

Mg)), Inconel (Cu + Cr + Fe), Brass, Bronze, Silver, Molybdenum etc.

§ This process is

used for joining various combinations of dissimilar metals like brazing and

braze welding.

§ Pipe work required

for high pressure steam lines, chemical and petroleum industries.

§ Welding of air

craft frame, jet engine casing, rocket motor casing.

§ Accuracy welding

of parts in atomic energy.

§ Expansions

bellows, transistors cases, instrument diagrams etc.

Advantages of Gas

Tungsten-arc Welding:

§ Gas Tungsten-arc

welds are stronger and more ductile.

§ No danger

corrosion due to no flux is used.

§ No post weld

cleaning because of no slag.

§ Wide variety of

joints can be made because no flux is used.

§ There is very

little or no smoke, fumes or sparks at all. This helps in making a neat and

sounder weld.

§ As the shielding

gas is transparent, operator can clearly observe the weld.

§ Fusion welds can

be made in merely all commercial metals.

Limitations

of Gas Tungsten-arc Welding:

§ Because of usage

of inert gas, coolant and coolant pump etc the cost of Tungsten

Inert Gas welding is very high.

§ Maximum thickness

of plate which can be joined by this welding process directly is up to 5mm.

§ For welding of

above 5 mm thickness plate additional filler rod must be used.

§ Even though

tungsten electrode is not melting but at high temperature the atoms of tungsten

may get diffused from the tip of electrodes and entering into the weld pool

which will increase the brittleness of weld bead.