V Belt

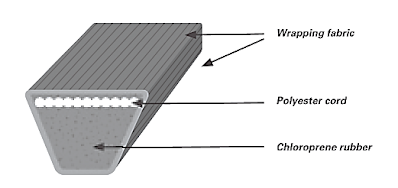

The v-belts are made of rubber with fabric cords to transmit power and its covered with a protective layer. The cords transmit the force from the driver to the driven pulley, thereby transmit the power. The number of cords are increased based on the force requirements. The rubber layer transmits the force in cord to the side layers.

V-belts are widely used in industry and automobiles because of its power transmitting capacity. the wedge shape of the belt increases the area of contact with the pulley there by increasing more friction which makes it ti carry more power without slip.

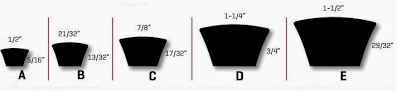

V-belt cross sections

There are different sizes of v belt cross sections named as A,B,C,D,E based on the width of belts. These are standard sizes manufactured by the belt manufacturers.

V-belts are preferred over flat belts

V-belts are preferred over flat belts the reasons follows,

- Power transmitted is more due to wedging action in the grooved pulley.

- Higher velocity ratio (up to 10) can be obtained.

- V-belt drive is more compact, quiet and shock absorbing.

- The drive positive because the slip is negligible

- They are rugged–they will give years of trouble-free performance when given just reasonable attention even under adverse conditions.

- They are clean–require no lubrication.

- They are efficient–performing with an average of 94-98% efficiency.

- They are smooth starting and running.

- They cover extremely wide horsepower ranges.

- They permit a wide range of driven speeds, using standard electric motors.

- They dampen vibration between driving and driven machines.

- They are quiet.

- They act as a “safety fuse” in the power drive because they refuse to transmit a severe overload of power, except for a very brief time.

- V-belts and sheaves wear gradually–making preventive corrective maintenance simple and easy.