Kinematics

of Machines in Mechanical Engineering

|

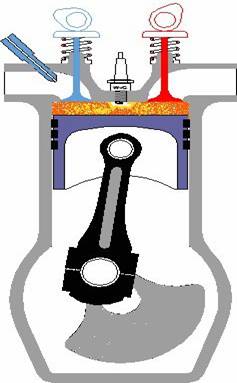

When

we refer to the study of the kinematics of machines, we’re referring to the

relationship between machine parts and how those parts behave as they move

through their ranges of motion. What this means is that there is

particular concern with the relative motion of machine parts, that is, how

they relate to each other, their position, distance, velocity, and

acceleration. When

speaking of the kinematics of machines, a mechanism is considered to be like

a chain with a system of links that are connected together. This

chain is constrained, meaning that independent movement of one part is not

possible. These parts are interconnected, and they all move

relative to each other. Motion in any one link of this kinematic

chain will result in a relative and predictable motion to each of the

others. Now, by “chain,” I don’t necessarily mean a chain in the

physical sense, but rather the fact that the parts of the mechanism are

linked together. To

illustrate what I’m talking about, let’s consider the gasoline engine shown

in Figure 1 below.

Figure

1 To

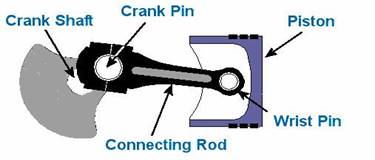

help you follow along, let’s turn the engine on its side and name the parts

of one of its kinematic chains. This is shown in Figure 2.

Figure

2

Suppose

you want to analyze how fast the engine’s

piston is moving at any given instant during its

operation. Suppose further that you know how fast the crank shaft

is turning. Where would your analysis begin? Well,

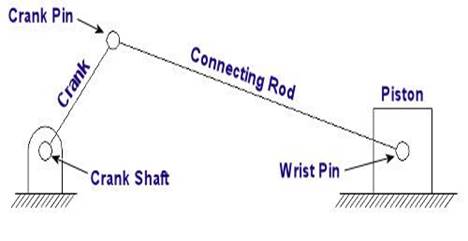

while studying the motions of machine parts, it’s helpful to draw the parts

first in skeletal form so that only those dimensions that affect their

motions are considered. Let’s represent the kinematic chain of

Figure 2 in skeletal form. See Figure 3

Figure

3

Lastly,

we embellish the skeleton with the depiction of angles that are at play as

the parts of our engine move, and we add the relevant symbols that will allow

us to build the equations we’ll be working with. This is shown in

Figure 4.

Figure

4

So,

as the engine runs, the crank AB rotates around the center of

the crank shaft A. The connecting rod BC is attached to the piston

at the wrist pin C. The piston moves back and forth as AB

rotates. Now here is where things get a little hairy, and for some

of you it may look somewhat like code or a foreign language. The

tangential velocity VB of the crank pin B is shown in Figure

4 as a vector. A vector is something which depicts both a

magnitude and direction. And since VB is a

“tangential velocity,” it is moving in a direction which is at a right angle,

that is, at a 90-degree angle in relation to the crank AB. This

relationship will always exist between VB and the crank AB. In

the posed scenario, VB is a velocity, so let’s say its

magnitude will be in units of inches per second. The magnitude of

the vector VB is then directly related to the speed of

crankshaft AB and is determined by this equation: VB =

2∏RN ÷ 60 Referring

to Figure 4, R is the distance between the center of

the crank shaft and the center of the

crank pin in inches. N is the rotational speed of crank AB in revolutions per

minute (rpm). If

one knows the crank angle X, the crank length R, and the connecting rod

length L in Figure 4, they can then use trigonometry to determine the

velocity of the piston. This velocity is represented by the vector

VC, and its magnitude, or value, would be found by using the

following equation… VC =

[VB] × [sin(X + Y)] ÷ [sin(90° – Y)] …where

the angle Y is found by: Y =

[sin-1(R ÷ L)] × [sin(X)] Analysis

of kinematics of machines would become even more complicated when complex

mechanisms like oddly shaped linkages, cams and followers, and gear trains

are involved. |