Pulleys as

a Work Input-Outut Device

|

In

our previous topic we saw how adding extra pulleys resulted in mechanical

advantage being doubled, which translates to

a 50% decreased lifting effort over a previous scenario. Pulleys are engineering marvels that make our lives

easier. Theoretically, the more pulleys you add to

a compound pulley arrangement,

the greater the mechanical advantage — up to a

point. Eventually you’d encounter undesirable tradeoffs. We’ll examine those trade offs, but before we do we’ll need to revisit the

engineering principle of work and

see how it applies to compound pulleys as a work input-output device.

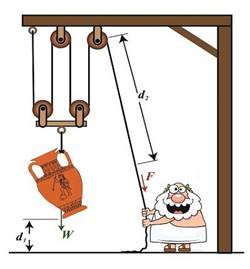

Pulleys as a Work Input-Output Device The

compound pulley arrangement shown includes distance notations, d1 and

d2. Their inclusion allows us to see it as a work

input-output device. Work is

input by Mr. Toga, we’ll call that WI, when he pulls his end of the rope

using his bicep force, F. In response to his efforts, work

is output by the compound pulley when the urn’s weight, W, is lifted off the

ground against the pull of gravity. We’ll call that work

output WO. In a

previous topic we defined work as a factor of force multiplied by

distance. Using that notation, when Mr. Toga exerts a force

F to pull the rope a distance d2 , his work input is

expressed as, WI =

F × d2 When

the compound pulley lifts the urn a distance d1 above the

ground against gravity, its work output is expressed as, WO =

W × d1 |