Gear

Reduction Worked Backwards

|

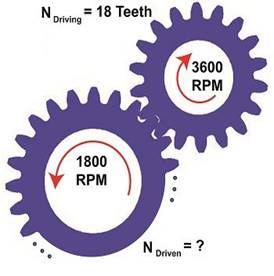

For

our example we’ll use a gear train whose driving gear has 18

teeth. It’s mounted on an alternating current (AC) motor turning

at 3600 (RPM). The equipment it’s attached to requires a

speed of 1800 RPM to operate correctly. What number of teeth

must the driven gear have in order to pull this off? If

you’ve identified this to be a word problem, you’re correct.

Let’s

first review the gear ratio formulas introduced in my previous two articles: R

= nDriving ÷ nDriven (1) R = NDriven ÷ NDriving (2) Our

word problem provides us with enough information so that we’re able to use

Formula (1) to calculate the gear ratio required: R

= nDriving ÷ nDriven = 3600 RPM ÷ 1800 RPM = 2 This

equation tells us that to reduce the speed of the 3600 RPM motor to the

required 1800 RPM, we need a gear train with a gear ratio of

2:1. Stated another way, for every two revolutions of the

driving gear, we must have one revolution of the driven gear. Now

that we know the required gear ratio, R, we can use Formula (2) to determine

how many teeth the driven gear must have to turn at the required 1800 RPM: R = 2

= NDriven ÷ NDriving 2

= NDriven ÷ 18 Teeth NDriven = 2 × 18 Teeth = 36 Teeth The

driven gear requires 36 teeth to allow the gear train to operate equipment

properly, that is to say, enable the gear train it’s attached to provide a

speed reduction of 1800 RPM, down from the 3600 RPM that is being put out

from the driving gear. But

gear ratio isn’t just about changing speeds of the driven gear relative to

the driving gear. |