Strengths

of Materials in Mechanical Engineering

|

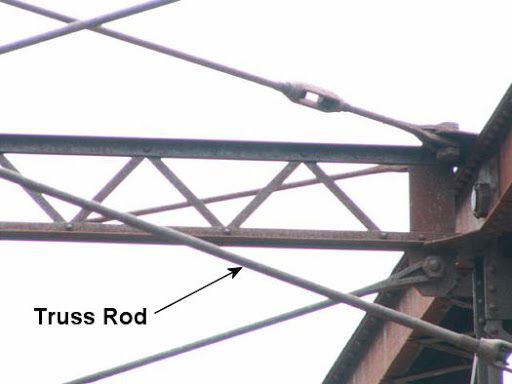

When

we looked at our statics example a few Topics ago, it was convenient to

consider the bridge beam as being perfectly rigid. In the real

world, a bridge beam is not perfectly rigid. When itís subjected

to external forces, like the weight of a truck sitting in the middle of it,

there is a tendency for it to bend, deform, change its

shape. If the external forces create bending and deformations that

are too much for the bridge beam material to handle, it will collapse. In

strengths of materials analysis, engineers must consider typical stresses

that will occur within objects like bridge beams, airplane wings, bolts, and

machine parts during use. Stress is a measure of force exerted per

unit area of a surface. Once the stresses are known, a material is

selected that is strong enough to keep the object from being bent, mashed,

stretched, and/or broken. To

illustrate this, letís consider an example of a simple

stress. Suppose you want to design a truss rod for a highway

bridge like the one shown in Figure 1. Specifications require that

the rod be two inches in diameter. Its purpose is to hold the

sides of the bridge together when vehicles travel across it.

Figure

1 Now

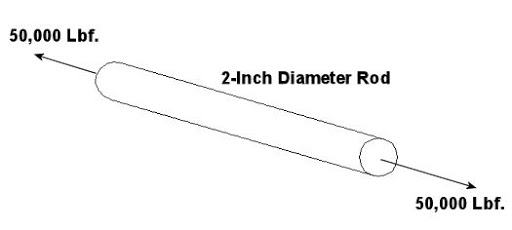

suppose that the bridge is to handle traffic to and from and iron

mine. Letís consider the scenario where a truck laden with iron

ore runs out of gas and comes to a stop in the middle of our

bridge. Under this load, static analysis reveals that the sides of

the bridge want to spread apart, putting a tension of 50,000 pounds force (Lbf.) on the truss rod as shown in Figure 2.

Figure

2 Since

the external force acting upon the truss rod and the diameter of the rod

itself are both given, the engineer would merely have to select the

appropriate material for the rod that would fall within the desired

parameters, that is, so as to keep our rod from pulling apart when

anticipated stressors such as a heavy truck is on the bridge. The

first step would be to calculate the tensile stress within the rod

itself. By tensile stress, I mean the stress in the rod due to the

forces that are trying to pull it apart. In our example, this is

relatively easy to assess: Stress

= [Tensile Force] ų [Lateral Cross Sectional Area of the Rod] The

lateral cross section of the rod is round, so its area would be πd2 divided

by 4, where the Greek letter π (Pi) has a value of 3.1416, and d is the

diameter of the rod. Therefore, the tensile stress would be: Stress

= [50,000 Lbf.] ų [π ◊ (2 in.)2 ų

4] = 15,915.49 Lbf./in.2 Knowing

the stress within the rod, the engineer would next have to select an

appropriate material for the rod thatís strong enough to do the

job. In our case, letís say we determine that steel is the best

material to use. But what type of steel? Well,

there are engineering handbooks with tables that list the mechanical

properties of all sorts of materials, including metals and plastics, and

along with those properties there is listed their ability to handle

stress. These mechanical properties were determined in laboratory

tests where carefully machined specimens of the materials were subjected to

measured stresses until they deformed and broke apart. They

include yield strength and ultimate strength, and these findings have been

duly recorded so that future engineers need not go through independent

testing of common materials themselves. Yield

strength is the stress that is measured when the test specimen begins to

stretch without any significant increase in force being applied to

it. Ultimate strength is the maximum stress that the material in

the test specimen can withstand before it starts to fail, that is tear apart,

break, collapse. Our

engineer would use the mechanical properties tables that are readily

available to him to select the appropriate steel alloy that would meet our

criteria, that is, has a listed strength high enough above the calculated

15,915.49 Lbf./in.2 tensile

stress to provide a sufficient factor of safety. Factors of safety

are listed in engineering books for yield strength and ultimate strength and

they are selected depending on how the forces are applied to a structural

component or machine part (e.g. steady, varying, or shock). When

strengths of materials analysis involves the solution of complex statics and

dynamics problems, things become a little less

straightforward. And when you are dealing with components having

odd shapes and a combination of stresses, say due to compression and torsion,

things become even more complex. In any case, engineers must have

extensive knowledge of the properties of materials in order to anticipate

factors at play in real world scenarios such as the one weíve been discussing. Ever

wonder why some steel is hard and brittle, and some is soft and bendable? |