|

When

Iím under a lot of stress I sometimes have the nervous habit of grabbing a

paper clip, straightening out the bends, then repetitively bending it back

and forth. Eventually the wire reaches a point where it just

breaks apart.

My

paper clip broke due to metal fatigue. Metal parts are said to

become fatigued when theyíre subjected to forces of a repetitive nature such

as occur due to twisting and bending. The metal cracks, then

eventually breaks due to the stress.

So

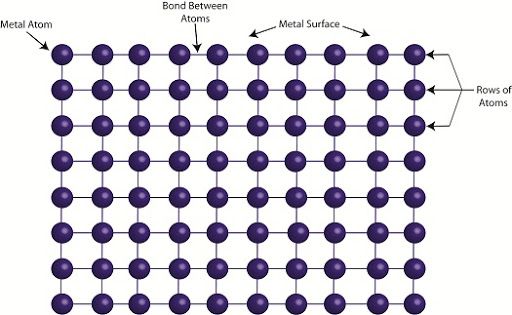

whatís happening when metal becomes fatigued? Figure 1 shows the

simplified atomic structure of a sample metal.

Figure 1

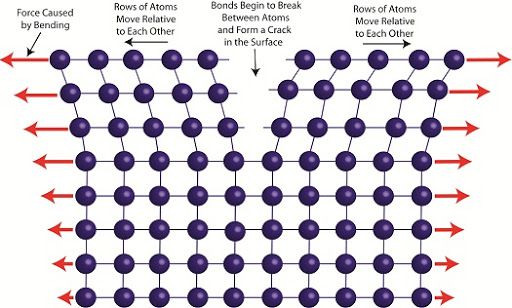

When

the metal is deformed, such as during bending, its rows of atoms are forced

to move with respect to each other as shown in Figure 2.

Figure 2

The

movement of rows of atoms leads to an alteration in structure, breaking bonds

between atoms. This results in small cracks forming along the

metalís surface, cracks which eventually migrate deeper inside the metal with

each subsequent bend. With time the metal will become so

compromised by the cracks that breakage occurs.

Metal

fatigue can occur in centrifugal clutch mechanisms as well. Power

tools such as grass trimmers typically operate between idle and working

speeds many times during a dayís usage. As we learned in previous

articles, when the engine runs at idle speed, the springs in the centrifugal

clutch mechanism stay retracted. As the engine speeds up, the

centrifugal force acting on the clutch shoes extends the

springs. Successive extensions and retractions cause the metal in

the springs to bend, and over time they, like my paper clip, will become

fatigued and metal springs will break.

|