HRSG Duct Burner - Combustion Air

Combustion Air

and Turbine Exhaust Gas

Temperature and

Composition

Oxygen used for

supplementary firing in HRSG co-generation applications is provided by the

residual in the turbine exhaust gas instead of from an external source of air.

Because this flue gas is already at an elevated temperature, duct burner

thermal efficiency can approach 100%, as relatively little heat is required to

raise the combustion product temperature to the final fired temperature

entering the boiler. TEG, however, contains less oxygen than fresh air,

typically between 11 and 16% by volume, which in conjunction with the TEG

temperature significantly affects the combustion process. As the oxygen

concentration and TEG temperature decrease, products of incomplete combustion

(CO and unburned hydrocarbons) occur more readily, eventually progressing to combustion

instability.

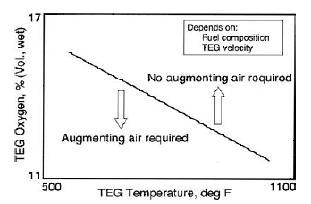

The effect of low

oxygen concentrations can be partially offset by higher temperature; and,

conversely, higher oxygen concentrations will partially offset the detrimental

effects of low TEG temperatures. This general relationship is shown in this

figure.

The burner can

then be designed to create a local high temperature condition

for stable combustion, while not allowing premature quenching by the remaining

excess TEG. Flame speed is another measure of combustibility and can be

calculated for unusual fuel constituents. The oxygen remaining from the turbine

combustion is usually many times greater than required for supplemental firing.

The final concentration of O2 after supplemental firing is frequently still

above 10%. In the extreme, a fully fired boiler is possible, with the residual

O2 as low as 2%. Fully fired HRSGs can produce large amounts of steam but are

rare because the economics favor the

power-to-heat ratio of unfired or supplemental fired HRSG.