DESIGN OF HEATING SURFACES

The first step in

the design of heating surfaces is determining the heat duties of different

components of the boiler heating surfaces. Atypical boiler would use the

following four types of heating surfaces:

Economizer

Evaporator

Superheater

Reheater (for reheat boilers)

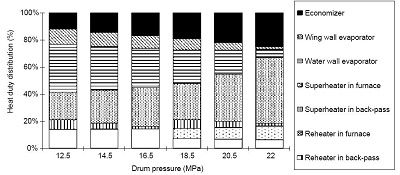

Heat duty of these

elements depends on the designed steam parameter of the boiler. It is best

illustrated by an example (Figure 1), which shows how the relative heat duty of

different boiler elements changes with steam pressure. As the steam pressure

increases, the heat duty of the evaporator decreases and that of superheater increases.

Figure 1

At low pressure

the evaporator duty is so high that a water wall or wing wall alone cannot

absorb the required amount of heat. So, a separate heating surface, called bank

tubes, is needed. After the heat duties of individual elements (economizer,

evaporator, superheater, and reheater) are determined by the steam table, their

disposition can be determined. From the viewpoint of heat absorption, a CFB

boiler may be divided into two regions, the CFB loop and back-pass

1.1. Primary Loop

The CFB loop

includes the furnace, cyclone/impact separator, loop-seal, and external heat

exchanger.

2.2. Secondary

Loop or Back-pass

The back-pass is

the section of gas pass between the exit of the cyclone/impact separator and

the exit of the air heater. The furnace usually accommodates:

Evaporator tubes

Parts of the superheater

Parts of or the

entire reheater

The economizer is

normally located in the back-pass between the superheater and

the air heater. Evaporator tubes may form the walls of the furnace and those of

the back-pass. Parts of it may also be located in the external heat exchanger.

Sometimes, the superheater tubes also form

parts of the back-pass enclosure. The disposition of the reheater and superheater tubes

in the furnace, back-pass, and external heat exchanger is the designer’s

choice. This choice is, however, influenced by the type of fuel, as shown

below. Some designs also use a steam-cooled cyclone