Compounding of

Impulse Turbines

The disadvantage of

De Laval type of turbine is that it’s extremely high speed, of the order of

30,000 rpm, cannot be employed for practical purposes. To reduce the high

speed, more than one set of blades are used. This is called “compounding of

impulse turbine”.

In the compounding

method, the steam jet velocity or the steam pressure is absorbed in stages as

it flows over the rotor blades. When “steam velocity” is absorbed in stages, it

is called “Velocity compound impulse turbine”. When “steam pressure” is

absorbed in stages it is known as “pressure compound impulse turbine”.

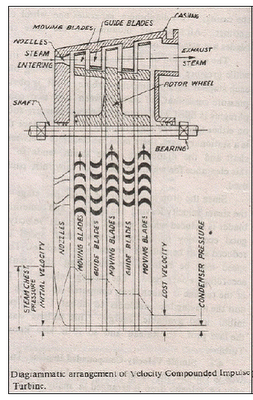

Velocity Compound Impulse

Turbine:

In velocity compound

impulse turbine, moving and fixed blades are placed alternately. Moving blades

are fitted with the wheel while the fixed blades are fitted with the casing.

The steam is

expanded in the nozzle from the boiler pressure to condenser pressure, to a

high velocity. It is then passed over the first ring of moving blades. Only a

portion of the high velocity of steam jet is absorbed by this blade ring, the

remainder being exhausted on to the next ring of fixed or guide blades. These

fixed blades change the direction of steam jet.

The jet is then

passed on to the next ring of moving blades. A further portion of the steam

velocity is now absorbed by this second moving blade ring. The process is then

repeated as the steam flows over the remaining pairs of blades until

practically all the velocity of the jet has been absorbed and the kinetic

energy is converted into mechanical work.

It should be noted

that the entire pressure drop takes place in the nozzle itself, the pressure

remaining constant, as the steam flows over the blades. Hence the turbine is an

impulse turbine. The Curtis turbine is an example of velocity compound impulse

turbine.

Pressure compound impulse

turbine:

In this type the

expansion of steam takes place in more than one set of nozzles and each set of

nozzles is followed by a set of moving blades. The total pressure drop of the

steam does not take place in the first set of nozzles, but is divided up equally

between all the sets of nozzles.