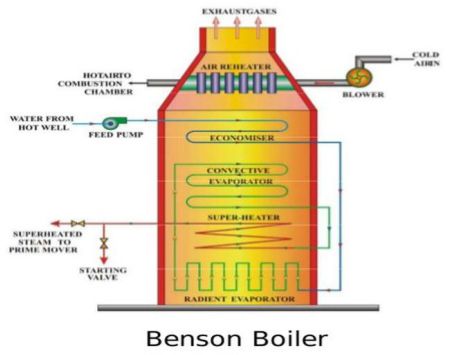

Benson Boiler

The presence of

steam bubbles in contact with the surface of tubes seriously impairs heat

transmission from the flue gases to water. By rising the boiler pressure to the

critical pressure of steam (225 kgf/sq.cm.),

this difficulty is overcome, as suggested by Mark Benson in 1922. At the

critical pressure water and steam have the same density and no bubbles are

formed.

The first modern

high pressure drumless boiler developed

by benson was put into operation in 1927 in

west Germany power station.

Working principle

of Benson Boiler:

This boiler has a

unique characteristic of absence of steam separating drum. The entire process

of heating, steam generation and superheating is done in a single continuous

tube.

Economiser

The feed water by

means of the feed pump is circulated through the economiser tubes. Hot flue

gases pass over the economiser tubes and the feed water is preheated.

Radiant evaporator

The feed water from the economiser flows into the radiant

evaporator with radiant parallel tube sections. The radiant evaporator receives

heat from the burning fuel through radiation process and majority of water is

converted into steam in it.

Convection

Evaporator

The remaining water

is evaporated in the convection evaporator, absorbing the heat from the hot

gases by convection. Thus the saturated high pressure steam at a pressure of

210 kg/sq.cm is produced.

Convection superheater

The saturated steam

is now passed through the convection superheater where

the saturated steam os superheated to

650íC. The radiant evaporator, the convection evaporater and

the convection superheater are all arranged

in the path of the flue gases.

Steam outlet

The superheated

steam is supplied to the steam turbine through the steam outlet.

Capacity

Capacity of benson boiler is about 150 tonnes/hr

at a pressure of 210 kgf/sq.cm. and at a temperature of 650íC. (Efficiency may be

improved by running the boiler at a pressure slightly lower than the critical

pressure).

Salient features

of Benson Boiler

1. As there are no drums, the

total weight of benson bolier is

20% less than other boilers. This also reduces the cost of the boilers.

2. As no drums are required, the

transfer of the benson parts is easy.

Majority of the parts may be carried to the site without pre-assembly.

3. Since no drum is used, this

is an once-through boiler and the feed water

entering at one end is discharged as superheated steam at the other end.

4. Circulating pump and downcomers are dispensed with.