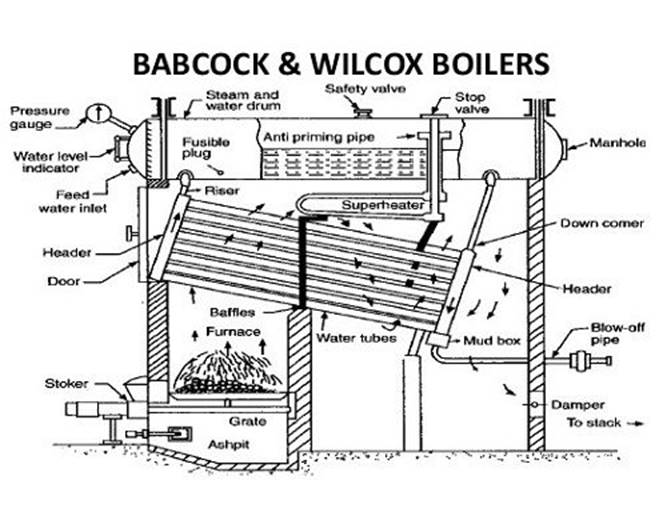

Babcock and

Wilcox Boiler

It is a water tube

boiler used in steam power plants. In this, water is circulated inside the

tubes and hot gases flow over the tubes.

Construction of Babcock

and Wilcox Boiler

The Babcock and

Wilcox Boiler consists of

1. Steam and water drum (boiler

shell)

2. Water tubes

3. Uptake-header and down corner

4. Grate

5. Furnace

6. Baffles

7. Super heater

8. Mud box

9. Inspection door

10. Damper

Steam and

water drum (boiler shell):

One half of the drum

which is horizontal is filled up with water and steam remains on the other

half. It is about 8 meters in length and 2 meter in diameter.

Water tubes:

Water tubes are

placed between the drum and furnace in an inclined position (at an angle of 10

to 15 degree) to promote water circulation. These tubes are connected to the

uptake-header and the down-comer as shown.

Uptake-header

and down-corner (or downtake-header)

The drum is

connected at one end to the uptake-header by short tubes and at the other end

to the down-corner by long tubes.

Grate: Coal is fed to the grate

through the fire door.

Furnace : Furnace is kept below the uptake-header.

Baffles: The fire-brick baffles, two in

number, are provided to deflect the hot flue gases.

Superheater: The boiler is fitted with a superheater tube which is placed just under the drum

and above the water tubes

Mud box: Mud box is provided at

the bottom end of the down comer. The mud or sediments in the water are

collected in the mud box and it is blown-off time to time by means of a blow

–off cock.

Inspection

doors: Inspection

doors are provided for cleaning and inspection of the boiler.

Working Babcock and

Wilcox Boiler:

Coal is fed to the

grate through the fire door and is burnt.

Flow of flue

gases:

The hot flue gases

rise upward and pass across the left-side portion of the water tubes. The

baffles deflect the flue gases and hence the flue gases travel in the zig-zag

manner (i.e., the hot gases are deflected by the baffles to move in the upward

direction, then downward and again in the upward direction) over the water

tubes and along the superheater. The flue gases

finally escape to atmosphere through chimney.

Water

circulation:

That portion of

water tubes which is just above the furnace is heated comparatively at a higher

temperature than the rest of it. Water, its density being decreased, rises into

the drum through the uptake-header. Here the steam and water are separated in the

drum. Steam being lighter is collected in the upper part of the drum. The water

from the drum comes down through the down –comer into the water tubes.

A continuous

circulation of water from the drum to the water tubes and water tubes to the

drum is thus maintained. The circulation of water is maintained by convective

currents and is known as “natural circulation”.

A damper is fitted

as shown to regulate the flue gas outlet and hence the draught.

The boiler is fitted

with necessary mountings. Pressure gauge and water level indicator are mounted

on the boiler at its left end. Steam safety valve and stop valve are mounted on

the top of the drum. Blow-off cock is provided for the periodical removed of

mud and sediments collected in the mud box.

Salient features of

Babcock and Wilcox Boiler:

1. Its overall efficiency is

higher than a fire tube boiler.

2. The defective tubes can be

replaced easily.

3. All the components are

accessible for inspection even during the operation.

4. The draught loss is minimum

compared with other boiler.

5. Steam generation capacity and

operating pressure are high compared with other boilers.

6. The boiler rests over a steel

structure independent of brick work so that the boiler may expand or contract

freely.

7. The water tubes are kept

inclined at an angle of 10 to 15 degree to promote water circulation.