Mechanical Workshop: Equipment

· Hurco CNC Machining Centres

· Okuma LT15 CNC Lathe

· Vertical milling machines

· Manual lathes

· Surface grinding

· Welding facilities

· 3D Printing and Scanning

· Vacuum forming

· Postgraduate student workshop Optimum D360 x 1000 Lathe, Optimum MF4 Vario

CNC Machining Centres

Our mechanical workshop is equipped with the following 2 Hurco CNC machining centres:

|

|

Used for the manufacture of fixtures and rigs for undergraduate and research projects these machine tools are the workhorses of the mechanical workshop. These machine tools can be programmed by the following means to machine most materials;

· Conversational programming Hurco have their own conversational programming feature called WinMax which allows programming in a question and answer format using multiple choice and fill in the blank questions. Operator prompts in plain English. No codes or computer languages are used.

· DXF Transfer this feature allows you to quickly import the 2D data from a dxf file. This feature enables the operator to select holes and machining operations, thereby creating a conversational program at the control.

· CAD/CAM the mechanical workshop uses Alphacam software for milling. Part files can be imported into our Alphacam system which enables the operator to generate tool paths for contouring, pocketing, engraving and hole-drilling complex parts.

HURCO VM-2 VERTICAL MACHINING CENTRE (complete with 4 axis)

Specifications | |

TRAVEL: |

|

TABLE: |

|

POSITIONAL ACCURACY: | Accuracy (at 68° F) |

SPINDLE SPEED: | 0 8000 rpm |

HURCO VM-10 VERTICAL MACHINING CENTRE

Specifications | |

TRAVEL: |

|

TABLE: |

|

POSITIONAL ACCURACY: | Accuracy (at 68° F) |

COOLANT SYSTEM: | Coolant through the spindle (CTS) |

CNC Lathe

|

Our mechanical workshop is equipped with an Okuma LT15 CNC lathe. This 5 axis machine tool is complete with twin chucks and turrets. Each turret consists of 12 stations which can carry live tooling with speeds of between 100-4500rpm. The machine uses a Fanuc based CNC control system, OSP 7000L and programming is carried out manually at the console.

Purchased in 2009 this machine was formerly used for the manufacture of artificial patellae. It is now used for the machining of runs of components such as consumable test pieces used in undergraduate laboratories, the machining of complex parts and it is also used for machining trials and tests for both research and commercial activities.

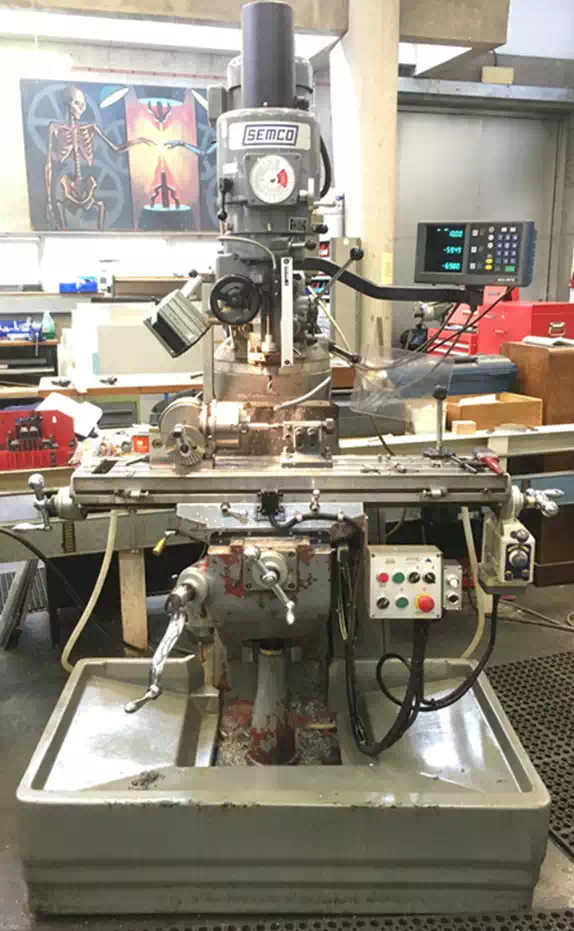

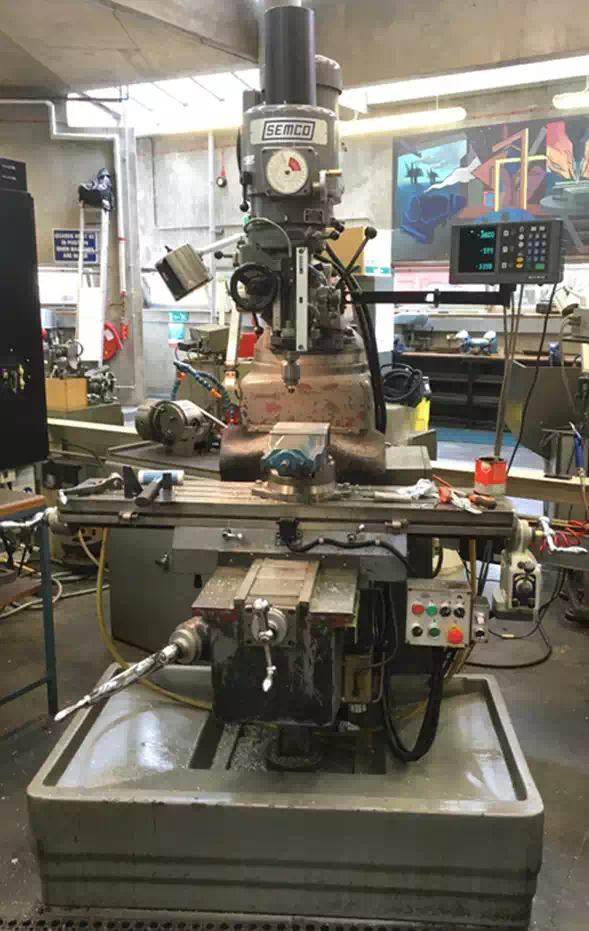

Conventional milling machines and lathes

Conventional milling machines are regularly used where a considerable amount of user interaction with the work piece is required. They are also used where larger, more awkward work pieces need modification or re-work or where the head of the machine needs to be tilted off to one side to machine an angle. Both SEMCO machines are used for training as part of the 3B8 Universal Design Innovation course. The Optimum OPTIMF4 VARIO milling machine and the Optimum OPTI F40 E Mill/Drill machine are assigned for use by researchers and postgraduate students who have carried out the workshop training course.

The mechanical workshop is equipped with the following vertical milling machines;

| Specifications: |

|

SEMCO FIRST LC-1 ½ VS | ||

| Specifications: |

|

SEMCO FIRST LC-185 VS | ||

| Specifications: |

|

Optimum OPTIMF4 VARIO | ||

| Specifications: |

|

Optimum OPTI F40 E - Mill/Drill machine | ||

Manual lathes

Our manual lathes are regularly used in the manufacture of prototype equipment used in undergraduate and research projects. The Mazak and Harrison lathes are used for training as part of the 3B8 Universal Design Innovation course. The Optimum D360 is assigned for use by researchers and postgraduate students who have carried out the workshop training course.

The mechanical workshop is equipped with the following manual lathes;

| Specifications: |

|

Harrison M300 | ||

| Specifications: |

|

Mazak Mate | ||

| Specifications: |

|

Optimum D360 | ||

| Specifications: |

|

Ursus 225 | ||

Surface grinding

Used to produce ultra-flat surfaces on metallic materials, our Jones & Shipman surface grinder is capable of achieving surface finishes of 0.2µm Ra. It is used for a wide variety of engineering projects such as;

· The precision grinding of syringes used in electro-spraying

· The precision grinding of parallel surfaces in press tooling

· To achieve ultra- flat surfaces prior to the application of strain gauges used in undergraduate teaching laboratories

| Specifications: |

|

JONES SHIPMAN 540 PRECISION TOOLROOM SURFACE GRINDER | ||

Welding facilities

The Dept. of Mechanical & Manufacturing Engineering has a dedicated welding bay where the following types of welding are carried out;

· MIG Metal Inert Gas

· TIG Tungsten Inert Gas

· Arc welding or Stick welding

· Gas welding

Our Technical staff are highly experienced in all types of welding processes including the brazing and silver soldering of materials. The 2MEMS10 Guitar Design Project and the 3B8 Universal Design Innovation Course are amongst the undergraduate programmes which are strongly supported by this area.

3D Printing and Scanning

|

The mechanical workshop staff have being providing a 3D prototyping service for over 15 years and have a wealth of experience in this process. Situated in the Build Base our Dimension 3D Printer uses the fusion deposition modelling process (FDM) to manufacture prototypes for research and undergraduate projects. We also have Roland Picza 3D Laser Scanner which is particularly suitable for the reverse engineering of components and models.

Vacuum forming

|

A vacuum forming machine is available for use in the mechanical workshop.

Specifications | |

Plastic Sheet Size | 300 mm x 450 mm |

Plastic types | Thermoplastics some plastics are better than others. HIPS - recommended |

Usable area | 250 mm x 400 mm |

Depth of draw | Up to 150 mm depending on shape |

Postgraduate student workshop

Equipped with an Optimum D360 x 1000 Lathe and an Optimum MF4 Vario milling machine, this area has been allocated for post-graduate students to carry out machining work on their projects. To gain access to these machine tools the postgraduate must have undertaken the workshop training course and successfully completed the lathe and milling exercises. For more information on this or to schedule a booking of the machines please contact mireilly@tcd.ie .

|

|