Universal Motor Speed Controllers

Universal motors are known to sometimes over-speed, perhaps dangerously and destructively, when run with no load.This article deals with different methods of universal electric motor speed control.

A motor which can be operated either on DC (direct current) or on single phase AC (alternating current) is called a universal motor. On both AC and DC, it gives approximately the same speed and output. Universal motors often run at dangerously high speed when operated at no load. This means that motor speed will be low at full load, but the speed of the motor will start increasing as the load on the motor decreases. Finally at no load, the motor will run at very high speed (perhaps about 20,000 rpm in some cases) and cannot made to run at less than about 2,000 rpm. The speed of universal motor varies just like that of a DC series motor. Being a series wound motor, it has a high starting torque and variable speed characteristics, and if the motor is started at no load, due to its high starting torque it will attain high speed quickly. Thus it is not advisable to start a universal motor at no load.

Speed (RPM) Setting of the Universal Motor

Designers use various methods to control the speed and to avoid the universal motor running at dangerous speed. One method is to build the universal motor into a device so that the motor would never run at no load. These types of motor are used for small applications that favor connecting the motor directly to the system that it drives.

Also they evolved various methods to set the RPM of the motor. One is through the use of a gear train to reduce the actual load speed.

Other ways of setting speed (RPM) of a universal motor are

· Centrifugal mechanism

· Resistance method of speed control

· Field tapping method of speed control

Centrifugal Mechanism for Speed Control of a Universal Motor

In the case where variable RPM (more than two desired settings for RPM) are required for universal motors, the centrifugal mechanism of RPM control is used. This speed control method is used for universal motors in applications like home food and drink mixers.

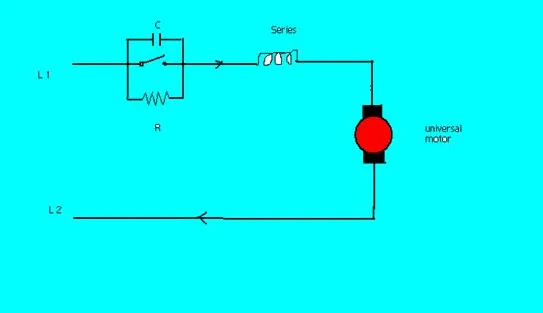

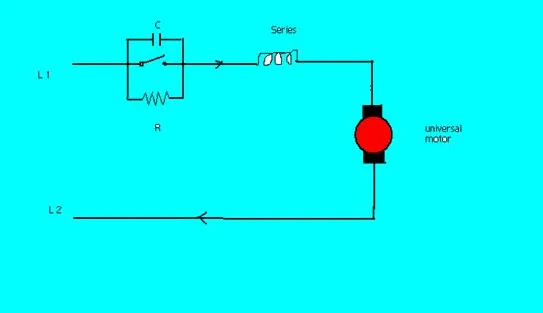

The setting of RPM is made by a centrifugal switch located inside the motor as shown in the diagram below. (Click the image to enlarge.) This centrifugal switch can be controlled or adjusted by means of an external lever.

If the motor speed rises above that set by the lever, the centrifugal device or switch opens two contacts and inserts a resistance R in the power circuit to the motor, which causes the motor speed to decrease.

If the motor runs too slowly, the centrifugal device will close the two contacts and short circuit the resistance so that the motor speed rises. This process is repeated so rapidly that variations in speed are not noticeable.

A resistance is connected across the centrifugal switch or device to perform this function. A capacitor C is used across the contact points in order to reduce sparking produced due to the opening and closing of these points. Moreover, it prevents pitting the of contacts.

Resistance Method for Speed Control of a Universal Motor

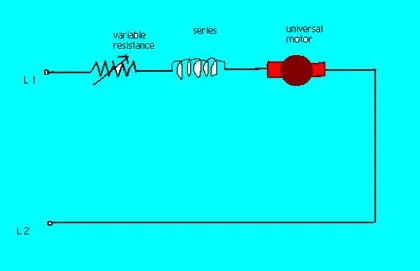

In this method, the speed of the electric motor is controlled or set by connecting a variable resistance R in series with the motor. Due to having the resistance before the motor, the current to the motor is reduced, which in turns reduces the speed of the motor according to the setting of that variable resistance. This type of speed control is employed for motors used in sewing machine. In this case the amount of resistance in the motor power circuit can be changed by means of a foot pedal. Also, a universal motor in drink and food mixers uses this method to set the speed and can be changed by setting the variable resistance.

Field Tapping Method for Speed Control of a Universal Motor

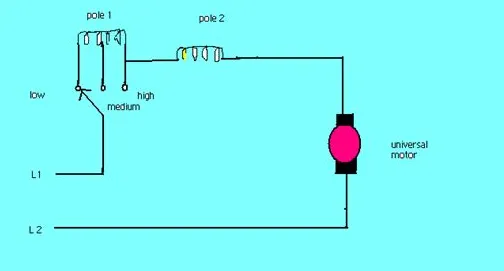

In this method, the field poles are tapped at various points so that the speed of the motor can be varied by varying the field strength. If there are more tappings from the field, then we can have various speeds for the motor. For this purpose of speed setting, the field poles are wound in various sections with different series of wire and taps are brought out from each section. Nichrome resistance wire is wound over one of the field poles and the taps are brought out from this wire.

Summary

A universal motor will run at dangerous speed at no load. Three methods of controlling the speed of a universal electric motor were discussed. These are the resistance control method, the field tapping method, and the centrifugal switch method. In the resistance control method, a variable resistance in series with the motor is used to set the RPM. In the field tapping method, the RPM is set by varying the field strength of the motor. Finally in the centrifugal mechanism method, a centrifugal switch is used that will connect a resistance in series with the motor if the motor speed increases and bypass the resistance if the motor speed is decreased.