Calculating the Stoichiometric Air-Fuel Ratio

Achieving fuel-efficiency in Internal Combustion Engines (ICE) is crucial to operation. In order to efficiently burn fuel in an ICE, you need the correct air-fuel ratio.

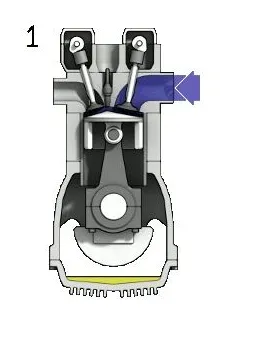

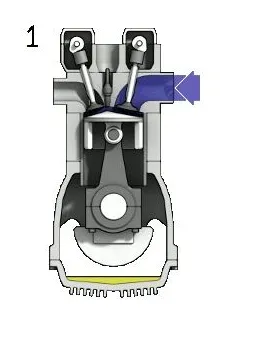

Internal combustion engines burn fuel to create kinetic energy. The burning of fuel is basically the reaction of fuel with oxygen in the air. The amount of oxygen present in the cylinder is the limiting factor for the amount of fuel that can be burnt. If there’s too much fuel present, not all fuel will be burnt and un-burnt fuel will be pushed out through the exhaust valve.

When building an engine, it’s very important to know the air-fuel ratio at which exactly all the available oxygen is used to burn the fuel completely or atleast to the best possible value. This ratio is called the stoichiometric air-fuel ratio.

Theoretically, this ratio will exist only for a stoichiometric mixture, which is an ideal mixture and in practice this mixture has never been formed for any machine so far. As every combustion cycle in an ICE is short lived, so it becomes almost impossible to achieve the ideal ratio. However, air-fuel ratios close to it can be achieved by modifying engine design and making use of proper admixtures and catalysts to keep a check on the pressure and temperature of the fuel.

The fuel combustion process takes place under very hot and pressurized conditions and to avoid any unsafe consequences, excess air operations are carried out. Excess air level keeps a check on the various factors like fuel composition variation, oxygen availability and pressure, that can lead to an explosion.

Air fuel meters or air fuel gauges are used to measure the air to fuel ratio of engines. Wideband oxygen sensors are used to measure the air-fuel ratio of ICEs. Mainly there are two types of band sensors, depending upon the purpose and type of engine. For heavy-duty and multi-purpose engines, using a wide sensor is advisable. For general diagnostic purposes, a narrow band sensor is most suitable. Advanced fuel ratio analyzers and gauges help a great way in monitoring the performance of an engine and tune it up according to the requirements.

Calculating the Ratio

The air to fuel ratio is the property of fuel and chemical composition of the fuel that defines the value for this ratio. Most of the fuels we use in internal combustion engines are hydrocarbons, and their burning will obviously result in the release of hydrogen and carbon as residuals, along with heat and pressure. Below is an example of the oxidation reaction of methane (natural gas) as a fuel.

· CH4 + 2(O2) → CO2 + 2(H20)

If we look up the atomic weights of the atoms that make up octane and oxygen, we get the following numbers:

Carbon (C) = 12.01

Oxygen (O) = 16

Hydrogen (H) = 1.008

· So 1 molecule of methane has a molecular weight of: 1 * 12.01 + 4 * 1.008 = 16.042

· One oxygen molecule weighs: 2 * 16 = 32

· The oxygen-fuel mass ratio is then: 2 * 32 / 1 * 16.042 = 64 / 16.042

· So we need 3.99 kg of oxygen for every 1 kg of fuel

· Since 23.2 mass-percent of air is actually oxygen, we need : 3.99 * 100/23.2 = 17.2 kg air for every 1 kg of methane.

So the stoichiometric air-fuel ratio of methane is 17.2.

When the composition of a fuel is known, this method can be used to derive the stoichiometric air-fuel ratio. For the most common fuels, this, however, is not necessary because the ratios are known:

· Natural gas: 17.2

· Gasoline: 14.7

· Propane: 15.5

· Ethanol: 9

· Methanol: 6.4

· Hydrogen: 34

· Diesel: 14.6

You may find it interesting that methanol and ethanol both have a very low air-fuel ratio, while the carbon chain length is comparable to methane and ethane. The reason for this is that alcohols like methanol and ethanol already carry oxygen themselves, which reduces the need for oxygen from the air.

The Bottom Line

In order to be able to judge if an air-fuel mixture has the correct ratio of air to fuel, the stoichiometric air fuel ratio has to be known. If the composition of a fuel is known, this ratio can be calculated rather easily.