V Belts

Lets us begin with a basic question.

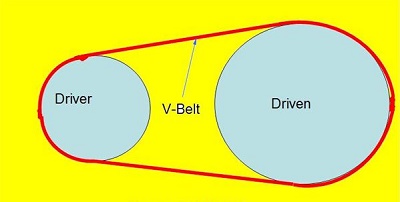

How do we transmit rotary power from one place to another? Well we have numerous

solutions and one of the solutions would surely be a V-Belt. A simple way of

defining any belt drive would be imagining two separate rollers being bound by

means of a thread that runs over its outer periphery. The thread acts as the

power transmitter conveying power from the driver member to the driven member.

In the actual V-Belt drive system, the thread is the V-Belt and the rollers are

called as pulleys.

V-Belts are friction based power or

torque transmitters. The power is transmitted from one pulley to the other by

means of the friction between the belt and pulley. The rubber used as the base

material plays a very vital role in this. This is quite similar to the friction

between the Tyre and road in the automobiles that enables the automobiles to

move on the road.

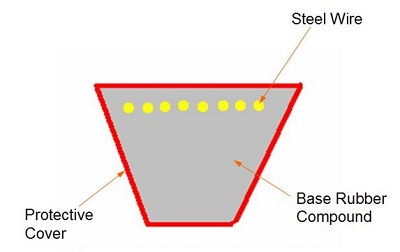

The V-Belt is

called so because of its cross section. The cross section of a V-Belt is

similar to that of the letter V. Let us know look into the constructional aspects

of the V-Belt. The V- Belt consists of the following

1. Steel Wires: The wires are of endless type having no joints in them. They provide the necessary reinforcement and strength to the V-Belt for transmission of the torque.

2. Base Rubber Compound: The wires are surrounded by a special rubber compound providing shape to the V-Belt. The compound also acts as a compression medium to absorb the shocks during power transmission.

3. Protective Cover: The protective cover is basically a layer of plastic which provides endurance for the rubber against the high temperature that is generated during the movement of the v-belt.

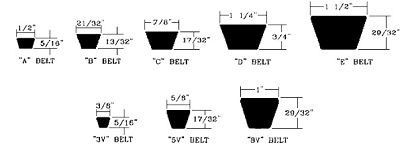

The V-Belts are basically classified

into 5 types or sections i.e. A, B, C, D and E. The categorization of

this is based on the cross sectional size of the belt and the amount of power

to be transmitted by the belt. The dimensions of various sections of the V-belt

are shown below. The included angle of the V-Belts is 40 Degrees.

Heres is a brief outline on the

power transmitting capacity of the each section type of the belt. The exact

transmission power of the belt will vary based on other criteria like arc of

contact, speed ratio, etc.

Section A Type - 0.1 kW to 3 kW

Section B Type 0.5 kW to 6 kW

Section C Type 1 kW to 12 kW.

Section D Type - 3 kW to 32 kW.

Section E Type 5 kW to 50 kW.

The values above indicate the

capacity of a single belt. In case a higher power is to be transmitted. The

belt can always be coupled with more belts in series to transmit the required

torque.

How is a V Belt Specified?

Heres a typical example of its

specification C 2032" . Here the C denotes the section type of the

belt, 2032 represents the nominal inside length of the belt,

Here are some of the features or

advantages of V- Belts

1. They transmit higher torque with lesser width and tension

compared to other type of belts.

2. They can be used in areas with very less arc of contact of

the belt.

3. They can be operated in speeds ranging between 5 to 30

m/sec.

The disadvantage of the V belt is

that, due to the wedging action of the belt and increased bending and windage

losses the efficiency of the belt is about 3% lesser than the other type of

belts. Apart from this the belt does have the tendency to slip at high loads

and gets easily damaged during slipping.