Timing Belts

Belt drives have a major role in

rotary power transmission. Just try to peep under the hood of your automobile

whether it’s a car or a SUV, you are sure to find atleast one timing belt in

it. Here’s a typical application of the timing belt in an automobile.

This shows the usage of the belt from

high torque transmission to very low torque transmission applications.

Let us now look into the aspects that

make this timing belt so unique for rotary power transmission.

1. The timing belts provide a positive drive; by this we mean

that there is no slip and relative motion between the belt and the pulleys thus

maintaining a constant speed ratio or even a specific timed position.

2. The constructional aspect of the timing belt i.e. the

teeth in the belt help in transmitting large torques and are capable of

withstanding high accelerations.

3. The lesser cross sectional thickness of the belt enables

the belt to be more flexible and at times they are able to drive various

pulleys in the system very efficiently.

Constructional Aspects of the

Timing Belt

The timing belt is basically a flat

belt with evenly spaced teeth in its inner circumference. The teeth provide the

advantage that a gear or chain drive posses – positive transmission of rotation

and power.

As shown in the figure above, the

timing belt consists of

1. Steel Wire or the tension member – This is usually a wire

that takes up the load and provided the reinforcement to the belt. The various

materials that are used for the tension member are steel wire, glass fibres,

Kevlar and polyester cords

2. Base Material (Neoprene) – A good coat of neoprene is

provided to the tension member in order to prevent any damage to it by oil and

moisture. It also acts as a wear resistor. The teeth formed by the neoprene are

shear resistant as they are molded integrally along with the other elements of

the belt.

3. Nylon Coating – A film of nylon fabric coating is provided

on the external layers of the belt which provides a low co efficient of

friction for the surfaces that wear out quickly.

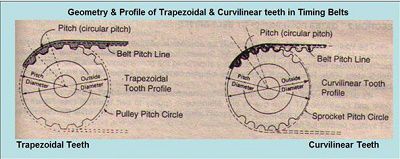

There are two types of tooth

shapes in the timing belt. They are

1. Trapezoidal Type – The trapezoidal type tends to have a trapezoidal

profile of the teeth that in turn mesh with a pulley possessing involute teeth.

The trapezoidal shape is actually that of an involute produced with an outside

diameter which is lesser than the pitch diameter.

2. Curvilinear Type – The curvilinear tooth profile is a circular arc. This

profile has some specific advantages like non tooth jumping due to increased

depth of the tooth in the pulley, higher contact area of the tooth and hence a

better power transmitting capacity, etc.

A comparison figure is shown below

indicating the profile types and geometry of the belt and the pulley

The belts are normally specified

based on the pitch of the teeth like 5mm, 8mm , etc. The width of the belt may

tend to vary based on the power or torque required to be transmitted.