What is a Spring Washer?

Washers are an essential element in

any mechanical design, as they help in uniform distribution of the applied load

and aid in securing the fasteners to their place. Spring washers endure stress

well under any working condition and reduce the vibrations in the equipment

considerably.

Types of Spring Washers

Spring washers can be broadly

classified into

○ Belleville Washers

○ Wave Washers

○ Curved Washers

○ Slotted Washers

There are innumerable numbers of

manufacturers supplying spring washers worldwide and they also offer custom

made solutions for your actual requirement. Spring washers are normally made

from high carbon steel for industrial applications and plastic washers are

intended for small applications. Now, we shall take a close look at all the

various spring washers and their use in different conditions.

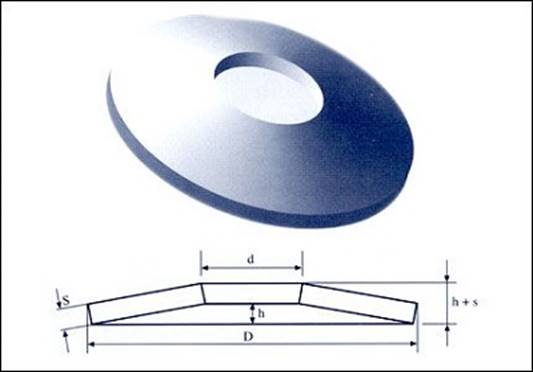

Belleville Washers

These washers are utilized when high loads are applied which may lead to minute deflections. They are conical in shape that enables to perform characteristics similar to a spring. They withstand higher loads admirably and secure the fasteners without much vibration or rattling. Belleville Washers allow a constant force to be applied at all times and as such, are suitable for industrial use with continuous operation like structural steel. They are useful in racing cars due to their great flexibility while turning at great speeds and in aircraft for oscillation dampening. The spring constant can be suitably changed by stacking them in the same or opposite direction depending on the required end result. This ability gives infinite possibilities which can be successfully utilized for operations.

Wave Washers

Wave washers are used when radial

space is constrained and moderate loads are applied in the operation. The

number of waves on the washer will be greater than three. The capacity of the

spring or the spring rate is directly proportional to the fourth power of the

number of waves designed on the wave washer. This gives flexibility to design

higher capacity washers.

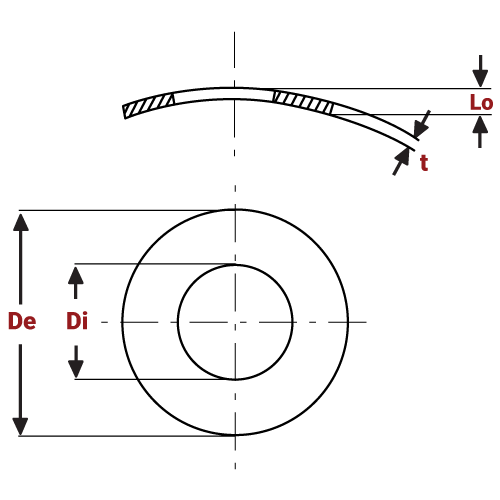

Curved Washers

Compared to the other two described

above, curved washers can be used for small operations. They are more useful in

controlling axial play rather than linear play, which limits their use to an

extent. They find greater use in motors, bearings, and seals that suffer axial

play more than anything else.

Slotted Washers

These are a combination of the

beneficial effects of a Belleville springs and a flat washer. They combine the

Belleville flexibility and point loading of a flat washer, which make them

useful in specific situations. Slotted washers can be employed gainfully where

the working part has high Inner diameter and small outer diameter like clutch

assemblies of automobiles or ball bearings in motors and generators. However,

the manufacture of slotted washers is complex and high precision is needed to

get the combined result of the Belleville and the flat washer.