GD&T Tutorial - Hole Basis

System vs Shaft Basis System

The limits and fits of geometric

dimensioning and Tolerancing can be either of hole basis or of shaft basis.

This GD&T tutorial will draw a comparison between the hole basis limits and

fits and the shaft basis.

As a mechanical design engineer you

may have to design a shaft or mating hole component or both. For such design

assignments, you have to decide the GD&T limits and fits, and for deciding

the limits and fits, you have to decide whether you want to go with the hole

basis system or the shaft basis system. And for making such a decision, this

article will be helpful.

Shaft and Hole Fits Basics

While dealing with shaft and hole,

you will come across the three basic types of fits: clearance fit, transition

fit, and interference fit or something in between these (like loose running

fit, sliding fit etc.). From the GD&T limits and fits tutorial you already

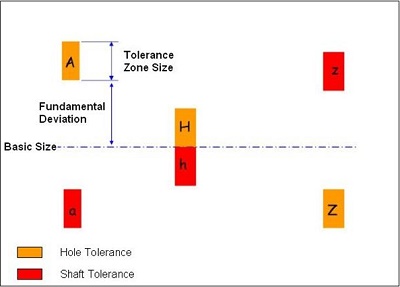

know that the shaft and the hole tolerance grades are represented like below:

Shaft Basis System

○ Take the maximum size of the shaft as datum for

the fit. That means, you have to take hole basic deviation class as h. (How?

Look at the above picture. The minimum tolerance of the h grade

is coinciding with the basic size).

○ Now, decide the tolerance grade (or IT number,

the number followed by the basic deviation, something like 6, 7 or 8) for the

shaft depending upon the machining process.

○ You should know the allowance (the minimum

clearance or interference between the shaft and the hole) from the application

of the shaft and hole. Add or subtract (for clearance or interference fits

respectively) the allowance value from the shaft diameter to get the minimum

hole diameter.

○ Apply the shaft tolerance grade.

Hole Basis System

○ Take the minimum size of the hole as datum for

the fit. That means, you have to take hole basic deviation class as H.(How?

Look at the above picture. The minimum tolerance of the H grade

is coinciding with the basic size.)

○ Now, decide the tolerance grade (or IT number,

the number followed by the basic deviation, something like 6, 7 or 8) for the

hole depending upon the machining process.

○ You should know the allowance (the minimum

clearance or interference between the shaft and the hole) from the application

of the shaft and hole. Add or subtract (for interference and clearance fits

respectively) the allowance value from the hole diameter to get the shaft

maximum diameter.

○ Apply the shaft tolerance grade.

Where to Use What

○ For a standard manufacturing process where hole

is manufactured by drilling, reaming, etc. and the shaft

by turning, etc., go for the hole base system, because altering the

hole diameter by a small amount is not possible for such cases, and on the

other, shaft diameter can be varied.

○ In the case where the shaft is used as a common

mating part for a large number of holes or shaft diameter is fixed and hole

diameter can be varied then it is better to go for shaft basis system.

Conclusion

GD&T limits and fits can be

applied either by the shaft basis tolerance system or by hole basis the hole

basis tolerance system. By and large, the hole basis system is most used in

industry, unless there are multiple parts with holes are fitted with a single

shaft.