Five Points You Must Remember While

Dealing With Practical GD&T

This geometric dimensioning and

Tolerancing tutorial will discuss points related to the practical application

of GD&T. So you can use this article as the checklist for applying

tolerance.

As a mechanical

design engineer you might be pretty clear about the individual concepts of

all the five categories of GD&T, but while applying practically the

geometric dimensioning and Tolerancing symbols to your design, you may find the

task bit challenging. The following points of the GD&T tutorial will

help you strategize applicable tolerance for your design.

Key Points of GD&T Application

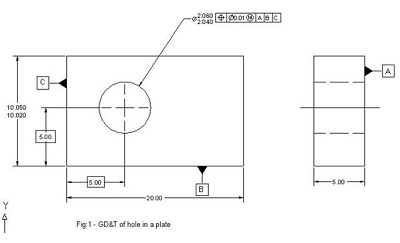

1. As soon as you are done with the

2D CAD drawing from the 3D CAD model, find out the feature

of size dimensions,where GD&T need to be applied. The fig-1 below

has a hole, for this purpose.

2. Next thing you have to do is to find out the

sufficient numbers of datum. We have used three (A, B, and C). Though we have

used the position tolerance symbol here, but the inclusion of

datum A in the GD&T frame is ensuring the

perpendicularity of the hole axis. So, from the above drawing, you will get the

positional tolerance of 0.01 at MMC and perpendicularity tolerance at MMC of

0.01.

3. If a feature of size does not contain any

GD&T symbol then the size as well as the form will be controlled by the specified

size tolerance (Rule#1). In the above figure, the datum surface B and

its opposite parallel surface is controlled by the dimension 10.050 –

10.020 and there is no GD&T symbol attached. So from the Rule#1 flatness

of datum B should not exceed 0.03.

4. Whenever you are looking for a clearance

5. fit, you should go for the MMC material

modifier and if you use the LMC modifier with your GD&T

value then the related fit will be interference fit.

6. Usage of MMC (or LMC) modifier with GD&T value,

allows utilizing the bonus tolerance. In the Figure-1, GD&T

is applied for MMC, means, for 2.040 diameter there

should be a positional tolerance of 0.01 and as the diameter increases the

positional tolerance also increase. For 2.060 diameter, the

positional tolerance become 0.03.

Conclusion

The concept of geometric dimensioning

and Tolerancing is important for a mechanical design engineer. Design engineers

sometimes find it challenging for applying the