Tools for Drawing Guidelines on

Metals

Marking out or scribing metals may be

performed for laying out the guidelines over the job which might exactly

represent the workshop drawing intended for the particular job work. This is a

lesson plan on marking out tools for metal.

While carrying out various

engineering processes like cutting, measuring, drilling, etc., marking out

accurate guidance lines through scribing over the job becomes very important so

that the desired operations are implemented flawlessly.

Various specifically designed precision marking tools are

employed for the above purpose.

The following lesson plan on some of

the important marking-out tools for metals provides a comprehensive study

regarding the subject, let’s study them one

by one:

The Scribing Block

It’s a precision instrument used for

accurately marking out lines over metals with respect to a standard parallel

true surface. The true surface is formed by a “marking

off table" which becomes an integral part of the whole system and is used

in conjunction with a scribing block.

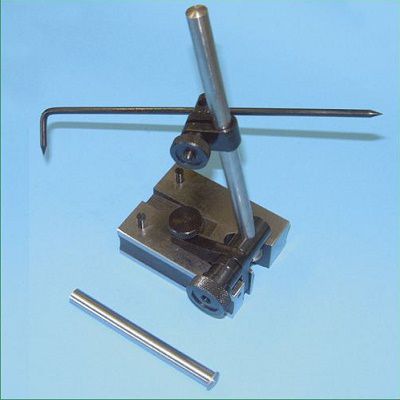

As shown in the figure a

scribing block typically consists of a firm pillar holding a scriber, the

system being supported by a machine finished

precise bottom base.

The base of the tool carries a

“Vee" groove intentionally dimensioned in the respective shape for

facilitating concentric guidance over cylindrical jobs and thus becomes

suitable for checking the accuracy of cylindrical tube bases.

The sharp straight and bent ends of

the scriber are used for drawing horizontal

lines and internal marking respectively over vertical surfaces.

The marker piece at the pillar’s

bottom end of the tool is used for drawing

lines over rough surfaces.

The pillar adjuster shaft carries a

small hole for adjusting the scriber directly into while the bigger hole is

included for associating a dial test Indicator.

A sliding dowel mechanism at

the base is used to adjust the position of

the scriber over the edge of the tool, thus enabling scribing parallel to the

edges.

Scribing blocks are classified according to the height of the

incorporated pillars.

The base of scriber tools is made up of case hardened low carbon steel, hardened

and tempered cast iron, or high carbon steel. Double terminated pointed scriber

ends and dowels are made by using hardened

and tempered high carbon steel. Other parts like rocking brackets, pillar, and

fine adjustment screw are made up of low

carbon steel.

How to Use a Scribing Block

Generally the operating procedure of the tool

involves the following steps:

The pillar must

be kept almost horizontal.

The bent end of the scriber

point should be positioned downward.

Keeping the scriber as close as

possible to the pillar, its angle should be held almost

horizontal.

The operator should always position

himself on the left side of the pillar and the scriber height adjusters.

The fine adjusting screw is kept at a neutral level.

It must be

ensured that while operating the scriber its point follows the base

of the unit.

Key Seat Rule

Also referred to as “Box Square",

these tools are used for marking out surfaces of circular bars and tubular

metals with lines parallel to their axis.

Key seat rules are also made up of hardened and tempered high carbon

steel and are classified with their lengths.

The tools accuracy

can be tested by first marking out a line through one of the edges of the tool over a parallel

bar and then turning the device to see whether the line exactly coincides with

the previous marking. If it does, the key seat rule is a true one.

Surface Plates

These are used for checking the

precision of flat surfaces and also for

marking out a supported small job in order to form a base from where further

measurements can be taken.

The tools are

made up of packed grain cast iron, are machine finished and

surfaced for perfection. The edges are made into

perfect right angles and the top flat.

How to Use Surface Plates

For checking the accuracy of flat

surface of a particular job, the flat top of the surface plate tool over which

the job is to be tested is first coated with

a sort of color film (“Marking"). Once

placed over it, the color gets transferred over the job’s surface, either

spreading uniformly (if it’s true) or indicating the high spots (in case it’s

incorrect).

Surface plates are portable units and

operated over bench tops. When not used for a longer periods

of time, its surface must be protected by applying oil over it and by keeping

it covered under its wooden enclosure.

The accuracy of surface plates is verified through another true surface called “Master

Surface". If a master surface is not accessible, three different surface

plates may be checked against each other for

comparing inaccuracies.

Vee Blocks

These devices come into play when

circular jobs are involved over surface plate tools, Vee Blocks are used for holding and supporting them in place.

They are also used in conjunction with

scribing blocks for supporting and setting the scriber to correct heights.

Vee blocks are

also made up of packed grain cast iron or case hardened mild steel.

They come in identical pairs, the pairs being marked with

identical numbers or symbol. The surfaces are accurately set with “Vee" at

right angles through machine finishing.

How Vee Blocks are Used

The adjustable parallel strips over

Vee Blocks allow its height to be raised by

bolting them over angle plates. Some clearance at the center permit the Vee

Blocks for accommodating rough edges or burrs generally associated with

rectangular or square jobs, thus ensuring right seating.

A pair of Vee Blocks may be checked

for accuracy by laying a parallel test bar in the “Vees" and verifying

that it’s precisely parallel with the surface table using a dial test

indicator. An affirmative result indicates that the pair is of equal heights.