Calculation Methods for Pulley

Systems

The article explains the three

fundamental systems of pulleys, covering their operational description and

methods for calculating their velocity ratio, mechanical advantage, and

efficiency.

From ancient times man

has always been keen in devising machines of different kinds for one basic

reason: relieving humans from tasks that are tedious and involve massive

efforts. Pulley mechanisms are one of these machines that have been serving mankind since the day they were invented.

A pulley mechanism consists of a wheel

and string assembly and is designed for

lifting heavier loads through a comparatively lower magnitude of effort. The

mechanism can be better understood by

studying the behavior of a “simple pulley."

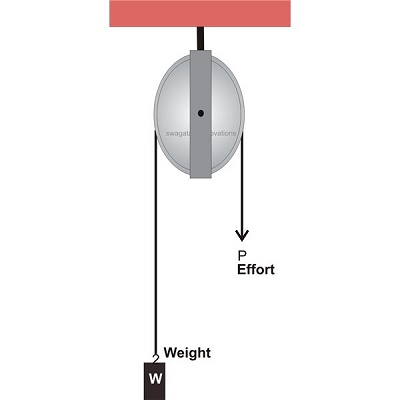

Simple Pulley: A simple pulley

basically consists of two components, the wheel and the string; the

wheel may be made up of wood or metal and includes a grove cut along its

circumferential periphery. The string is allowed to

slide or pass through this groove with a load that is to be lifted fixed at one

of its ends and an effort applied at the other end in order to lift the load.

The pulley wheel is supported over a rigid

frame about its central axis.

The applied effort through

pulling of the string rotates the pulley and pulls the load upwards, helping

the load to be lifted with ease.

A classic example of this

mechanism can be witnessed over wells where

the pulley and rope are used for lifting water-filled buckets.

Some important observations made by

assessing this mechanism which may prove useful while

calculating them are described below:

○ The weight of the pulley block can be ignored as

its too small compared to the load that’s required

to be lifted or rather moving heavier weights become more desirable for

efficient response from these devices.

○ The friction developed on either side of the

pulley across the string contact can also be ignored,

again due to its negligible occurrence.

○ Calculations prove that the Mechanical Advantage

(MA) and Velocity Ratio (VR) of this mechanism is unity under the discussed

operational conditions.

In order to improve MA, VR, and

efficiency, the above pulley mechanism is dimensioned through

some intelligent combinations of extra pulleys and strings. These specialized

pulley mechanisms are classified as follows, so let’s study

them one by one.

First System of Pulleys

As can be seen from the diagram, the

lowermost pulley here carries the load (being lifted), which is fixed and hangs

over the axle of the pulley.

An end of the string T1 attached

firmly to an upper rigid frame, passes across the groove of this pulley and

attaches its other to the axle of the second.

The same string configuration is

repeated for the all the pulleys until the first pulley where the preceding

pulley’s string end instead of attaching to the axle of the topmost pulley,

slides down across its groove and ends towards the other side where the effort

can be finally applied.

The applied effort lifts the

weight and also the entire pulley system

under the topmost pulley.

Now, suppose if the applied effort

raises the weight W and the pulley P1 by x meters, in order to maintain

tightness of the string attached to its axle and balance the movement, pulley

P2 has to move through a distance of 2x meters.

The same theory

applies to the pulley P3 which now must show a relative displacement of 2 ×

(2x) = 22x, also the pulley P4 must compensate the act with an upward lift of 2

× 22x = 23x and finally for the pulley P4 which is fixed with the upper frame,

the string takes over the sequence to produce a displacement equal to 2 × 23x =

24x.

Therefore Velocity Ratio = Distance

covered by effort/Distance covered by load

= 24x/x = 24

Therefore if the above pulley system

carries n number of pulleys then VR = 2n

And MA = W/P (standard equation)

Also efficiency ɳ = MA/VR

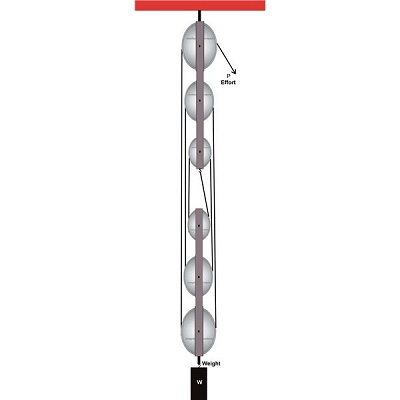

Second System of Pulleys

The diagram below shows the second

system of pulleys consisting of two blocks. The upper block carries three wheels which freely rotate about their individual

central axes and are supported over a single common axle which is firmly fixed

to a rigid upper frame.

The lower block also contains similar

pulley and axle mechanism; however the whole

structure is supported by one end of an intertwined string configuration

passing through the pulleys, as illustrated in the figure. The other end

termination of the string which passes across the

uppermost pulley is used for the application of the effort.

The weight is supported by the axle of the lower block.

Through some observation it becomes

obvious that for displacing the weight by some distance, say x, the applied

effort has to move through a distance nx, where

n is the total number of pulleys in the system.

Therefore, the velocity ratio can be

expressed as nx/x = n

And as usual MA and the efficiency may be

written as given for the first system of pulleys.

Third System of Pulleys

It is quite

identical to the first system; however by looking at the figure it

becomes clear that the operations involved are just in the reverse process.

The velocity ratio of the

system can be tracked by following a unit

movement of the weight.

Suppose, the attached weight is moved by a distance of x meters by the effort

applied at P, this will cause an instantaneous slackening of the strings

involved.

For supporting the action, the

strings will go through a sequential tightening movement through the pulley

rotations.

Therefore the slackening of string 1

(assuming to be equal to x meters) is compensated by pulley number two, which

comes down and covers a distance of 2x meters.

Also with slackening of string 2,

x1 gets pulled across a distance of 2x –x =

x meters.

Continuing further, with x1 being

pulled through x meters, x2 gets pulled through a length of 2x +x = 3x = (22 –

1)x.

The procedure is followed on to keep

the relative position of pulley 3 constant and string 3 is pulled across a

distance of (2 × 3x × x) = 7x = (23 – 1)x, and finally string x4, which is

actually the effort, crosses a distance of (2 × 7x + x) = 15x = (24– 1)x meters.

Therefore the VR of the system can be

equated as = Distance Covered by Effort/Distance Covered by Weight = (24 – 1)x/x = 24 – 1, for the present example which consists of 4

pulleys.

In general for a particular third

system of pulley having n number of pulleys, VR = 2n – 1.

MA and ɳ may

be taken as discussed for the previous systems.