Types of Flexible Coupling – Bibby

Resilient Couplings

Named after its Inventor Dr. James Bibby in 1917, this coupling is still one of the most sought after flexible

couplings for heavy shock applications. Let us now look at the constructional

features of the coupling.

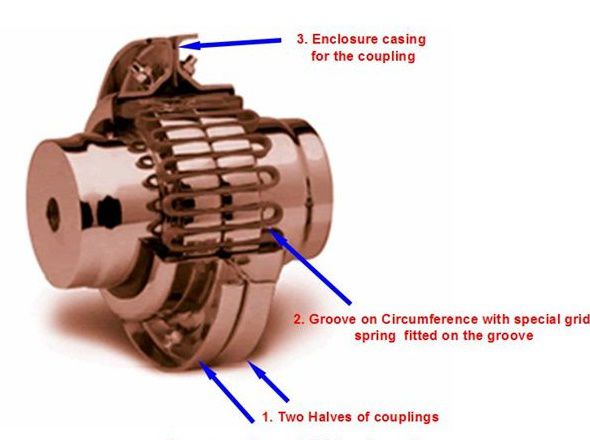

○ The Coupling consists of two flanges or hubs

specifically mounted on the drive and the driven shafts respectively. These

hubs contain axial grooves cut on their circumference.

○ The two couplings are

joined or held together by means of a specially designed grid spring.

○ The total assembly is enclosed in a casing or

shell filled with grease for low speed applications or, in high speed application with high viscosity oil.

Now let’s look

at the working aspect of the coupling and how it tends to reduce vibration and

prevents the build up of resonance in the

system.

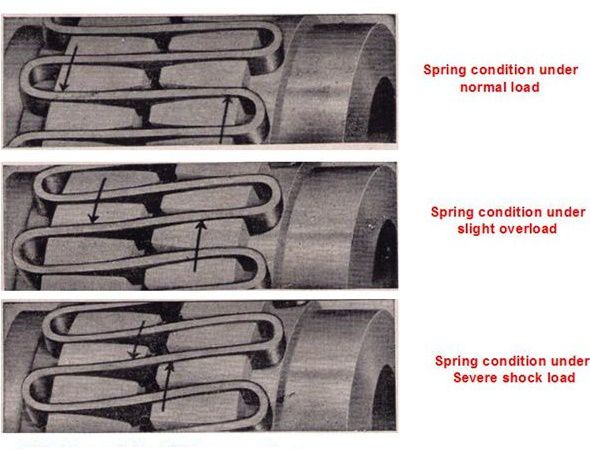

a.) The specially designed spring is

wound up through the grooves forming a series of resilient bridges throughout

the periphery of the coupling.

b.) The grooves are tapered up at the

edges (see photo) in order to provide extra flexible spans to the spring at

normal loads and tends to support the spring at the sides whenever overloading

occurs.

c.) The stiffness of the spring

depends on its unsupported length of each of its flexible span. The unsupported

length tends to vary with the loads producing a varying stiffness for the

coupling based on the loading.

d.) This action tends to produce a

detuning action altering the torsional vibration frequency of the system that

prevents the build-up of resonance.

Some applications of Bibby

Couplings are

○ Cement Mills – in grinding and crushing

machinery.

○ Cranes

○ Conveyors

○ Turbines

○ Marine Auxiliaries

○ Paper Mills

Bibby couplings can be used for

applications with powers varying from as low as 1 h.p to about 100,000 h.p.

per 100 rpm of the coupling. Correspondingly the

couplings are available in varying sizes ranging from 100mm diameter to 4000 mm

diameter.

Bibby couplings are capable of taking

axial and radial misalignments to a very small extent only. It is necessary for

the user to ensure that both axial and radial misalignments are kept to the minimum possible.

Selection procedure for Bibby

Couplings:

The selection of the Bibby

coupling is mainly based on the torque being

transmitted by the coupling. Each coupling has a characteristic value for the

torque transmitted by it to the revolutions per minute of the coupling.

The rating of the coupling is given by

Rating = Maximum power to be

transmitted in h.p/ r.p.m of

coupling

In order to account for contingencies

like shocks, sudden stops, stalling, etc. a factor of safety is to be considered during selection of the coupling.

Rating of coupling to be Selected =

Max. power of coupling* Factor/ r.p.m. of coupling

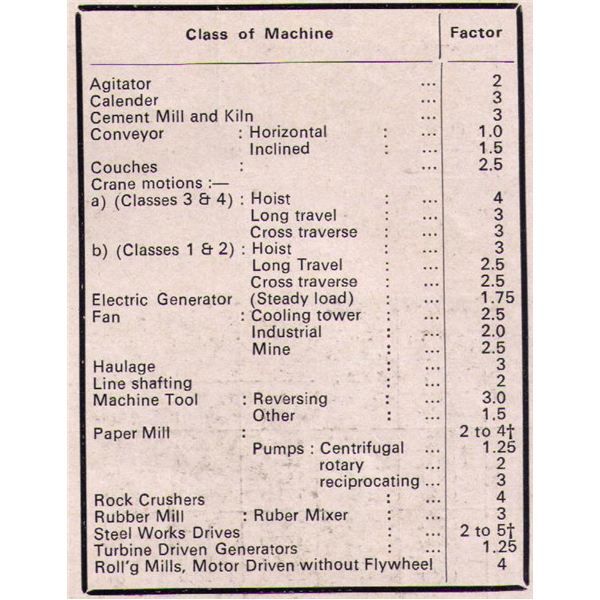

The chart containing the factors

to be considered is given below based on the

application and driving machinery.

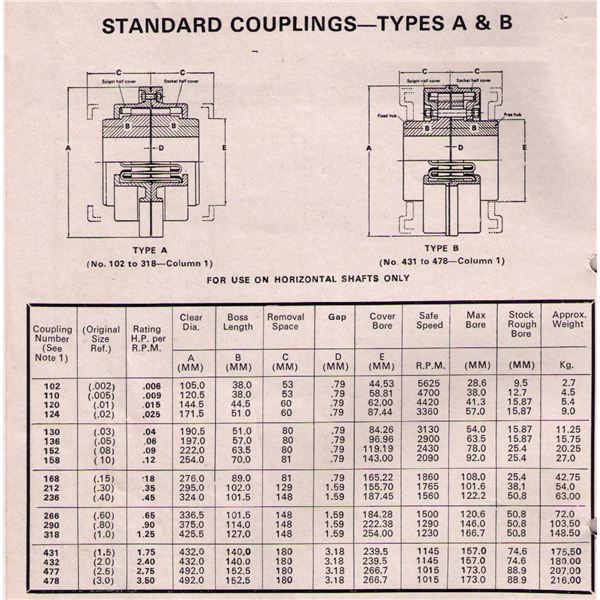

See the selection chart below for the

selection of corresponding coupling based on the power. Note: This chart is an

indicative for the selection of the Bibby coupling. Kindly refer to an actual

manufacturer's catalog for selection as

ratings may vary from manufacturer to manufacturer.