Types of Flexible Coupling – Gear

Couplings

Couplings are

used as connecting elements between two shafts. The complexity in

the type of connectivity, the power to be transmitted and

the area of application tend to play a vital role in the selection of the type

of the coupling.

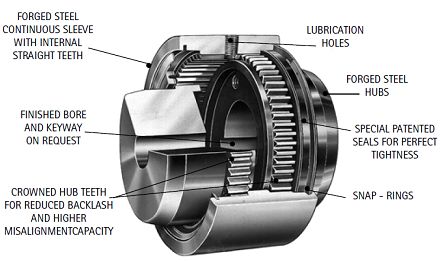

Gear Couplings belong to the category

of flexible couplings that are capable of transmitting very high torques. Constructionally the gear coupling utilizes the

advantages of gear engineering; practically the coupling is a complete gear

assembly. Let us now look into the constructional aspects of the coupling.

○ The gear couplings consists of a forged sleeve

with internal teeth cut on its inside. The forged sleeves are normally two

halves possessing internal gears in both of them. In certain cases the forged sleeve tends to remain a single piece.

○ Two hubs with external teeth containing

the same number of teeth as in the internal gear is present with each one being mounted on the driven and driver shaft

respectively. The tooth profile of the external teeth is

normally crowned in order to take up more loads.

○ The entire assembly in normally enclosed and is

provided with gaskets at the joints and O-rings at vantage points in order to

prevent the leakage of the lubricant filled inside the coupling,

○ Lubrication plugs are

provided at vantage points in order to lubricate the couplings

during predetermined intervals of time.

Tooth forms in the Coupling:

Three types of external teeth are used in gear couplings. The only difference is the

manufacturing methodology of the same.

a.) Straight Teeth:

The external teeth in the hub are straight. During the condition of

misalignment in the coupling the contact

pattern between the internal gear and the external gear tends to be line type

of contact as shown in the figure.

b.) Crowning with constant radius:

The external teeth are barrel shaped with a constant radius in order to

increase the area of contact and move the area of contact to a near middle

portion of the teeth.

c.) Crowning with variable radius:

The external teeth are barrel shaped with a variable radius instead of constant

radius. This increases the area of the contact significantly compared to that

of the constant radius crowning.

The maximum degree of misalignment permissible

in gear couplings is from 0.5 Degrees to 1.5 Degrees. This varies with the size

of the coupling being used.

Selection procedure for gear

coupling:

The gear couplings are selected based on the torque ratings.

○ 1. The torque transmitted by the coupling is to

be determined.

○ 2. Based on the application the appropriate service factor needs to be determined.

○ 3. The equivalent torque is to be determined by

multiplying the service factor with the torque transmitted.

○ 4. Select the coupling based on the equivalent torque value calculated.