Enveloping Worm Gear Design

Advantages

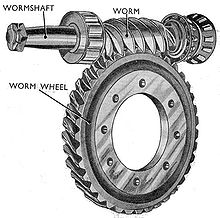

What is a Worm Gear?

For transmitting

power between two non-parallel and non-intersecting shafts worm gear is used. A

typical worm gear looks like below:

When you need very high reduction ratio and you have space constraints or donít have the provision of using many gears, then you can think of using a worm gear for your design. You can design a worm gear box

for

a reduction ratio as high as 200:1. The only problem with this type

of gear box is the heat generated during power transmission. So you have to

have provisions for a sufficient numbers of fins and/or fans for the gear box.

Another problem with

this gearbox is that there is very less contact area between the worm thread

and the gear teeth and more backlash. Backlash is the amount of rotational

clearance available between the gear teeth and the worm thread. You can check

the backlash of a pair of gears by changing the direction of rotation of the

worm; the more freely you can rotate the worm, the more backlash is present.

Backlash makes an ordinary worm gear inappropriate for the precision

applications like robotics and medical applications. In order to avoid this

problems, enveloping worm gear design concepts arose.

What is a Enveloping Worm

Gear?

In the enveloping

worm gear design, either the contour of the gear teeth or the contour of the

worm threads or the contour of the both is modified in such a way that the

amount of the contact surfaces increases. Thus, you will get increased accuracy

from the worm gear.

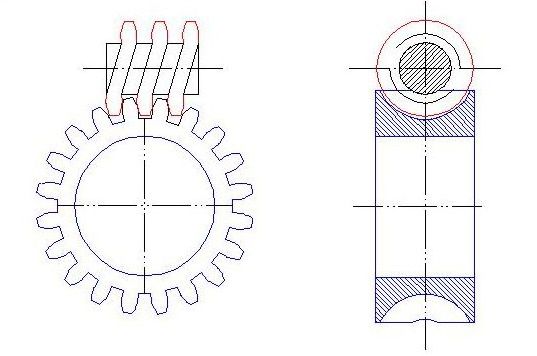

When only the

contour of the gear teeth is modified like below to get the increased amount of

contact surface then the arrangement is called single enveloping worm gear.

If you observe the

right hand side view, you can see that the profiles of the gear teeth are

curved to match the circular profile of the worm thread. But still you can see

from the left hand side view that, hundred percent engagements is there only

for one thread (the middle one) and the two of the side threads have partial

engagement and this is not desired. This problem can be solved by using double

enveloping worm gear design.

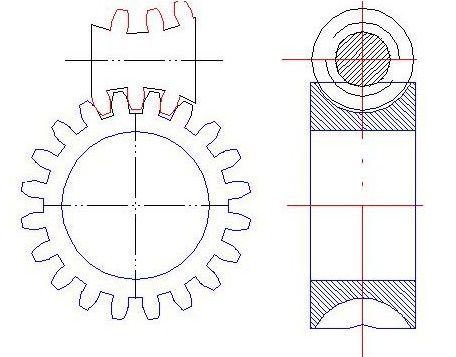

In double enveloping

worm gear, the teeth profile of the gear as well as the shape of the worm

threads are modified to achieve better engagement.

From the right-hand

side view of the picture you can see how the shapes of the worm threads have

modified in line with the circular shape of the gear teeth. Now, you can see

the complete engagement throughout the length and width of the worm gear and thatís

what we want.

Conclusion

The worm gear is

most suitable for higher reduction ratio. But the problem with the ordinary

worm gear is less contact area between the worm threads and gear teeth. This

problem can be solved using an enveloping worm gear. However, major challenge

for the enveloping worm gear is itsmanufacturing process. Finding a

supplier for the enveloping worm gears is not as easy as that of ordinary worm

gear.