Analyzing Abnormal

Vehicle Vibration Tendencies

Drive

train vibration issues, if not treated in a timely fashion, can cause serious

catastrophic damage to your gearbox. Do you know what the possible causes of

the vibration issues are and how to get rid of them?

Theory of Vibration

○ When a continuous

exciting force acts upon a body and cause some repetitive motion (back and

forth or up and down) over the same body or over the adjacent bodies, the

phenomena is called vibration.

○ Either the

reciprocating or the unbalanced rotating components are the ideal sources of

vibration.

○ Vibration in a drive

train or in gear box is generated by either or both of the following two ways:

■ Vibration is

transferred (in the form of pulsating torque) from engine, engine auxiliaries

and clutch (or torque converter).

■ Vibration is

generated locally at drive train unit.

○ The vibrations from

its source to the other parts are transmitted through the transfer path. For

example, the vibration generated at the unbalanced tire can cause the steering

wheel to shake. In this case the suspension system and structure of the vehicle

acts as transfer path.

○ In case the

vibration is generated locally at the drive train unit then the vibration will

definitely change its characteristics with the selection of different gear

ranges and in the neutral position there should be no vibration at all.

Causes and Control

Controlling

and eliminating drive train vibration issues can be implemented only after

studying the following affecting parameters:

○ Gear tooth

type: The longer the duration of contact between the mating teeth, the

less the operational vibration of the gear pair. Helical gear teeth produce

less vibration (compared to spur gear teeth) due to their higher contact ratio.

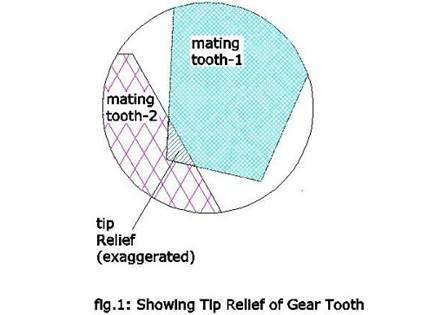

○ Teeth profile: In applications

where using helical gears is not possible (due to the side thrust of helical

gears), less vibration can be achieved for the spur gear teeth by removing

small amount of the materials at the tooth tip. The procedure is called tip

relief (Refer to Fig.1).

○ Gear teeth surface

finish: The smoother the gear surface, the less the vibrations. For

example, eeth manufactured

by the honing process should have less vibration compared to teeth manufactured

using the shaving process. Having said that, it should also be considered that

smoother finishing processes are also often the costlier ones.

○ Lubricants: The thicker the

lubricants used, the less the vibration that is transmitted outside the

vibration source. However, thicker lubricants increase the transmission losses

of the drive train.

○ Torsional vibration

resonance: The rotating frequency of the individual gears should not fall in

the critical range (approximately 10%) above and below the natural frequency of

the system, or else resonance (large vibration) will occur.

○ Alignment: Any misalignments

between the driving and driven shaft also can cause vibration.

○ Corroded

teeth: If there is substantial differences between the both the sides of

the teeth then excessive teeth wear can be suspected for the vibration.

○ Bumps: Small picks on the

teeth surfaces can cause vibration; the picks can be identified easily, because

these picks will be shiner than the surrounding surfaces.

○ Bearing

failure: Bearing failure can be detected either by checking the axial float

or by visual inspection. Rectifying failed bearing can prevent catastrophic

damage of the gear box.

Vibration Monitoring Tools

The

simplest vibration measuring tool is called a sirometer or vibra tech.

It has a cantilever wire whose length can be adjusted by rotating a wheel and

as the length changes, the natural frequency of the wire also get changed.

After placing the sirometer on

the component to which the vibration to be measured you have to keep on

adjusting the wire length until you see the wire is oscillating vigorously (resonance).

From the tool you can then note the frequency reading.

To sum it

up, finding the exact source is key first step to be taken correctly. After

reaching there, check the symptoms and accordingly try the appropriate

solutions to get rid of the drive train vibration issues.