How to Measure Torque Requirements

for Gear Box

The torque

requirements of a gear box are normally drilled down from the application,

where the gearbox is coupled. For example, in ready

made concrete mixer machine, the main torque requirement and speed

of the output shaft of the gear box comes from the rotating drum. And depending

upon the gear reduction ratio the torque requirement is transferred to the

input shaft of the gear box. So, from the above discussion it should be clear

that the torque requirement of the gearbox input shaft will be different. And

you can find out the torque requirement by two ways: Strain gauge

method and Calculation method.

Strain Gauge Method

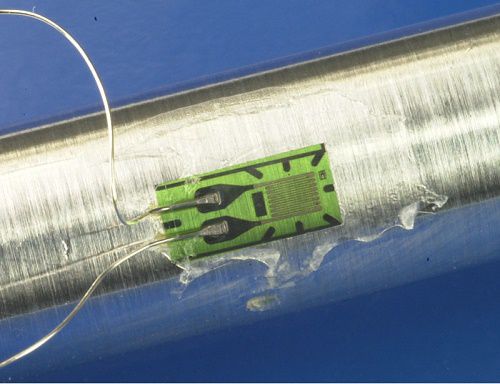

If you apply torque to a shaft then the fibers of the shaft will be under torsional stress. Or, in other words, the fibers will be subjected to the tension in one direction and will be subjected to compression to another direction. The fact is true for the gearbox input and output shaft as well.

The strain

gauge transducer can sense the tension and compression of the gear

box shaft under torsion and can measure the torque in it.

The strain gauge

transducer has two parts: the strain gauge and the transducer display and

processing unit. The strain gauge senses the torque and sends the signal to the

transducer signal processing unit, which in turns connected to the digital

display unit. The display unit displays the torque value.

So, for finding out

the torque requirement of the gear box input and output shaft, you have to

place the strain gauge transducer to the shafts.

Calculation Method

You can use the

standard equations available for calculating the torque requirement of

the gear box shaft. The basic equations used here are:

P (KW) =

(2/60000)*Π*N (Rpm) *T (N.m)……………..Eqn.1

N1/N2 = M2 /

M1………………..Eqn.2

Where,

P – Power in KW

N – Speed in Rpm

T – Torque in N.m

M- Number of teeth

of the respective gear.

First thing you have

to know is the Power requirement of the application. Take

the concrete mixer example again, after you know the power

requirement of the rotating drum, you can apply the Eqn.1 and

find out the torque requirement (T) of the gear box output shaft.

Next, use the Eqn.2 to

find out the speed (N) of the input shaft of the gear box and again use

the Eqn.1 and find out the torque requirement of the input

shaft of the gear box.

Conclusion

We have two methods

for how to measure torque requirement of gear box: either by using the strain

gauge transducer or by the calculation method using the known mechanical

design equations. Fitting the strain gauge is a skillful job

and requires different installation procedure prescribed by the respective

strain gauge manufacturer.