Torque Converter: What it is

and How it Works

The vehicles and

machineries with automatic transmission does not have a clutch, instead,

it has a torque converter. But, how a torque converter works or solves the

purpose of a clutch? To give you an idea, it works on the same principle as

the fluid coupling.

How a Torque Converter

Works

As the name

suggests, it converts the torque of the engine and transmits it to the

transmission system.

As soon as the

flywheel of engine starts rotating, the torque converter housing as well as the

pump also starts rotating in same speed and direction. Because of the profile

of the pump blades, the fluids inside the torque converter are pushed out

centrifugally. Because of the pressure developed by the pump, the fluids are

forced into the blades of the turbine and make it rotate in the same direction

as the pump. The fluids enter to the outer periphery of the turbine and leave

from the inner periphery and reaches to the stator blades there. The function

of the stator is to guide the incoming fluid from the turbine to reach at a

specific angle to the pump.

If the turbine is

rotating at a speed lower than that of the pump (i.e., when the vehicle is

accelerating) then the fluids from the turbine hits the front sides of the

stator blades and the one way clutch prevents it from rotating. In this

condition the fluids leave from the stator hits the pump at a “helping"

angle to increase the torque (or multiply the torque) and thus increase the

speed of the turbine.

When the vehicle

achieves its constant speed, then the angle at which the fluids leaving from

the stator change and no more torque multiplications happens.

While retarding, the

speed of the turbine increases than that of the pump and the fluid from the

turbine hits the back sides of the stator blades and make the stator rotate at

the same direction as the pump and turbine and the fluid from the stator hits

the pump in such angles that the torque reduces.

Major Parts of a Torque

Converter

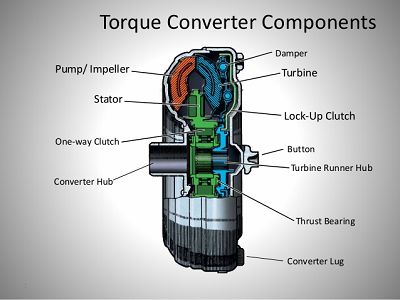

A torque converter

typically has three major components: impeller or pump, turbine and stator or

reactor.

Impeller or

Pump: The

pump is made up of blades and works very similar to a centrifugal pump. It

is mounted rigidly with the torque converter housing (shown in blue). The whole

torque converter housing in turns is mounted rigidly with the flywheel. So, it

rotates with the flywheel.

Turbine: Constructions of the

turbine is very much similar to that of the pump but the orientation of the

turbine blades are opposite to that of pump. The turbine is mounted on

transmission input shaft.

Stator or

Reactor: The

stator has very complex guiding blades arrangements. It is mounted by a one way

clutch with the transmission housing. The one way clutch allows the stator to

rotate in one direction and prevent it from rotating to another.

Conclusion

You will find the

use of the torque converter in almost all sort of automatic transmission

vehicles: from passenger cars to heavy off highway vehicles. The design of the

blades of the turbine, stator and the pump is the key of how effectively a

torque converter works.