Do You Know Why Electric Motors Generate Reverse Electromotive

Force?

Brushless

DC motors (BLDC) are used where there are limitations in the use of the

brush-type DC motors. In this article we discuss how it is possible operate a

DC motor with no brush arrangement and also explain the back EMF in a brushless

DC motor (BLDC).

A DC

motor is a one which operates on a supply from a DC source. The DC source may

be either a DC generator or from a battery. DC motors may be classified as:

○ Series wound DC motor

○ Shunt wound DC motor

○ Compound wound DC

motor

○ Separately wound DC

motor

In all

types of DC motors, the supply is given to both stators to make it as an

electromagnet. This supply is necessary because the operation of a DC motor

depends on the attraction and repulsion principles of magnetism.

In the

stator, the supply voltage from a DC source is given directly, and in the rotor

of DC motor it is supplied by means of a brush arrangement. But in case of

brushless DC motors, this supply voltage to the rotor should be supplied

without any brush arrangement. Brushless DC motors are more complicated than

ordinary DC motor with brush arrangements, but certain applications needs this

brushless DC motor, and hence it exists.

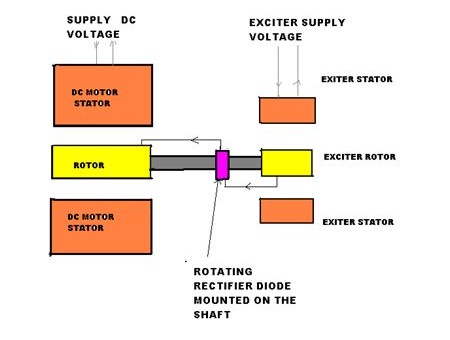

In a

brushless DC motor (BLDC), we have an exciter rotor mounted on the same shaft

of the rotor of a DC motor. This exciter stator induces an EMF when a small

voltage is applied to the stator of this exciter. The voltage induced in the

exciter rotor is an AC voltage and this is rectified to DC by means of a

rotating rectifier diode arrangements mounted on the same shaft of the motor.

The rectified DC voltage is applied to the rotor of DC motor, and there is no

brush required so the DC motor with this type of complicated arrangement is

called a brushless DC motor (BLDC).

Understanding Back EMF in Electric Motors

A notable

disadvantage associated with BLDC motors is the generated back EMFs by its

winding when operated. The following discussion explains the origin of these

unwanted back EMFs.

According

to Faradays law of electromagnetic induction, when a current carrying conductor

is placed in a magnetic field (that is, if the conductor cuts the magnetic

field), an EMF is induced or produced in a conductor and if a closed path is

provided, current flows through it.

When the

same thing happens in a brushless DC motor (BLDC) as a result of motor torque,

the EMF produced is known as “back EMF." It is so called because this EMF

that is induced in the motor opposes the EMF of the generator.

This back

EMF that is induced in the brushless DC motor (BLDC) is directly proportional

to the speed of the armature (rotor) and field strength of the motor, which

means that if the speed of the motor or field strength is increased, the back

EMF will be increased and if the speed of the motor or field strength is

decreased, the back EMF is decreased.

This back

EMF created acts as a resistance, and we all know that any resistance in a line

reduces and opposes the current flow so if the speed of the DC motor or field

strength is increased, the back EMF increases which in turn increases the resistance

to the current flow in windings and hence only less current is delivered to the

armature of DC motor. Also if the speed of DC motor armature or field strength

decreases, the back EMF decreases, which in turn reduces the resistance and

hence more current flow to the armature of DC motor.

When the

DC motor is first started, there is no back EMF induced and as discussed above

there is maximum current flow from the DC generator or distribution lines to

the motor armature and as a result the motor toque will be maximum. In this

case there is no resistance offered by back EMF. The only resistance available

is the motor winding resistance.

During

normal operation (rated speed) of DC motor, the back EMF induced will be

maximum which reduces the motor armature current to its minimum level and as a

result the motor torque is also reduced.

When the

load on the motor is increased, the motor speed (RPM) is decreased and this

reduces the back EMF. This decrease in back EMF automatically increases the

motor torque thereby bringing the motor to its rated speed.