Modern Steam Turbines

There are two basic types of steam

turbines: Impulse and Reaction turbines. The impulse turbine is normally used

for high and intermediate steam turbines, whereas the reaction turbine is used

for low steam turbines. However modern turbines can also be a combination of

these two types.

Steam Turbines in Power Plants

Overview

The type of rotating equipment we

will look at in this article will be steam turbines used for power generation.The first steam turbine for this

application was invented by Sir Charles Parsons, and his first one came on line

in 1888. This was a great advancement from the other steam turbines around at

the time as it was a revolutionary multi-stage turbine which used the expanded

steam much more efficiently than the conventional single stage ones. We shall

look therefore at a typical modern Parsons Turbine used to generate power for

the National Grid, which at present is responsible for producing 80% of the

world's electricity.

Types of Steam

Turbines

There are two basic types of steam turbines:

Impulse and Reaction turbines. The impulse turbine is normally used for high

and intermediate steam turbines, whereas the reaction turbine is used for low

steam turbines. However, modern turbines can have a combination of these two

types in the high/low pressure stages.

Steam Flow Through the Turbine

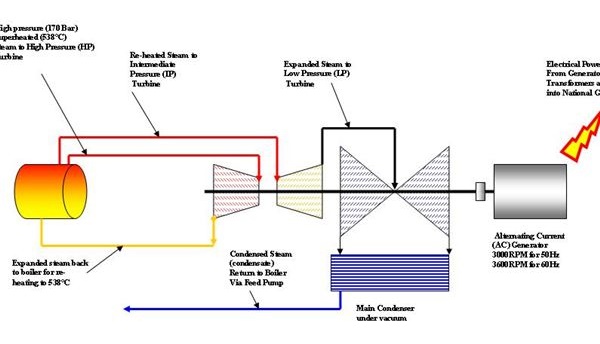

The sequence of steam passage through

the turbine is as follows: (see image)

Superheated steam (above 500°C and

170bar) is injected into the high pressure (HP) stage of the turbine through a

ring of static nozzles. These nozzles project the steam at the precise angle

onto the rotor blades to extract the maximum energy from it.

The blades on the HP rotor are quite

small and the diameter of the rotor gets larger from the steam entrance to the

exit where it is redirected to the boiler to be reheated to 500°C. This

reheated steam is injected into the intermediate stage (IP) of the turbine, in

which, like the HP stage, the rotor gets progressively bigger in diameter from

the steam entrance to exit (the blade sizes become larger as the pressure of

the steam drops).

Finally the steam is directed into

the LP section of the turbine where the blades are the largest, to accommodate

the flow of lower exhaust steam from the IP. The steam exits the LP stages and

enters the condenser, which is under a vacuum and, the resulting condensate is

pumped back to the boiler by the feed pump.

Image

Assembly and Maintenance of

Steam Turbines

Very fine clearances that are

imperative to the efficient operation of the turbine exist between the rotating

turbine blades and the fixed blades/nozzles. Therefore it is essential that

great care be employed in assembly in order to maintain these tolerances.

Another important point to be considered before assembling the rotor to the

turbine is the balancing of the rotor, which is normally carried out by a

specialist company. Also crucial to smooth running is the alignment of the

turbine drive shaft to the generator drive shaft, which can be carried out

using dial gauges or the more modern method of laser shaft alignment.

With speeds of 3000 RPM for 50 Hz and 3600 RPM for 60 Hz, these measures along

with the initial ‘bedding in’ of the main white metal bearings will ensure that

no vibration takes place during operation.

Running a Steam Turbine up from

Cold

Finally, there are strict procedures

to be adhered to when the turbine is stationary and when running up from cold.

It is essential that only superheated steam is used as any water can severely damage

the blades. Because the condenser is normally under a vacuum, if a vacuum is

applied when the turbine is off-line, the turning gear should be used to slowly

rotate the shaft. This avoids the possibility of the vacuum bowing the turbine

shaft. It is imperative to "warm through" the turbine inlet and

exhaust steam system several hours before the turbine/generator is due to come

on line. This is carried out (after disengaging the turning gear), by running

the turbine for one minute at 10-15 RPM then stopping it for one minute before

repeating. This ensures that all three stages of the turbine along with the

pipework and pumps are fully expanded to working conditions and the lube oil is

up to optimum temperature and pressure.